BogusSVO

Well-known member

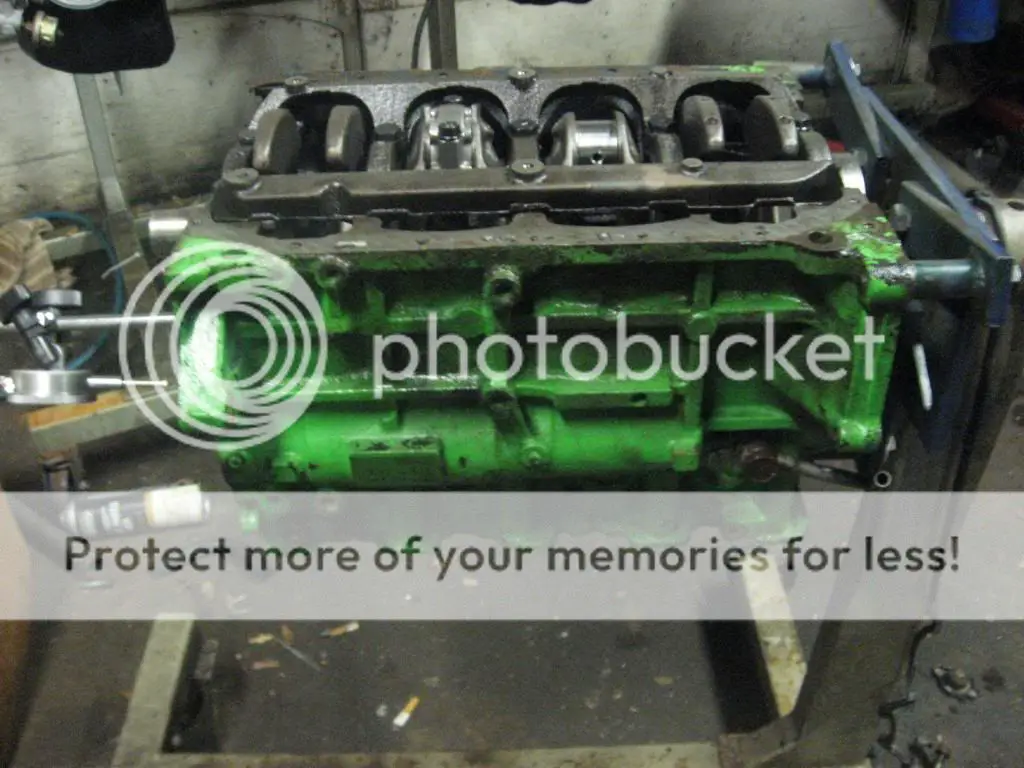

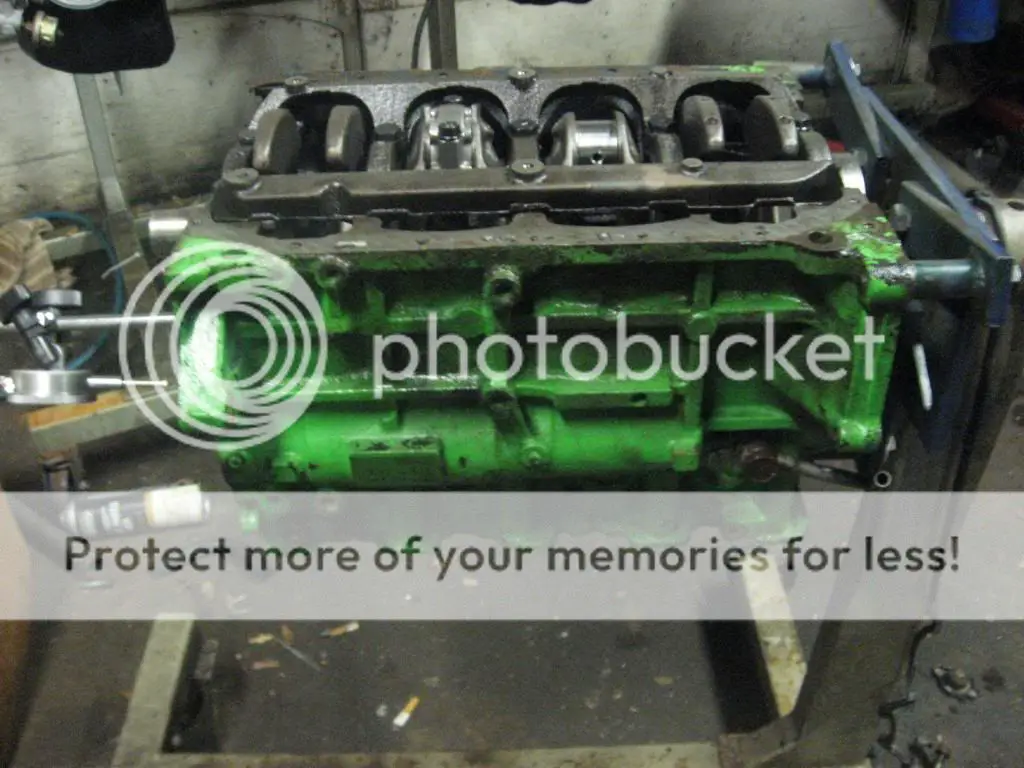

Short block teardown and inspection

7bolt 4g63T

I had this short block dropped off at my shop about 8 months ago as a core turn in. The story I was told was it had less than 2000 miles on it. It was shipped in from another machine shop that specializes in the 4g engine.

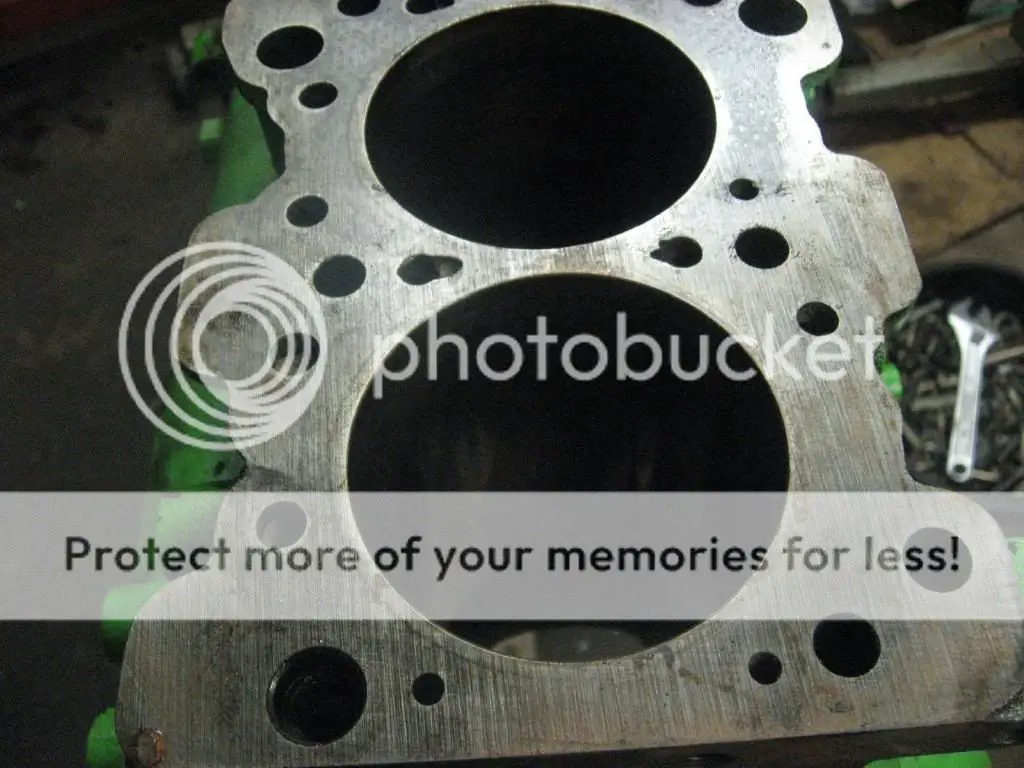

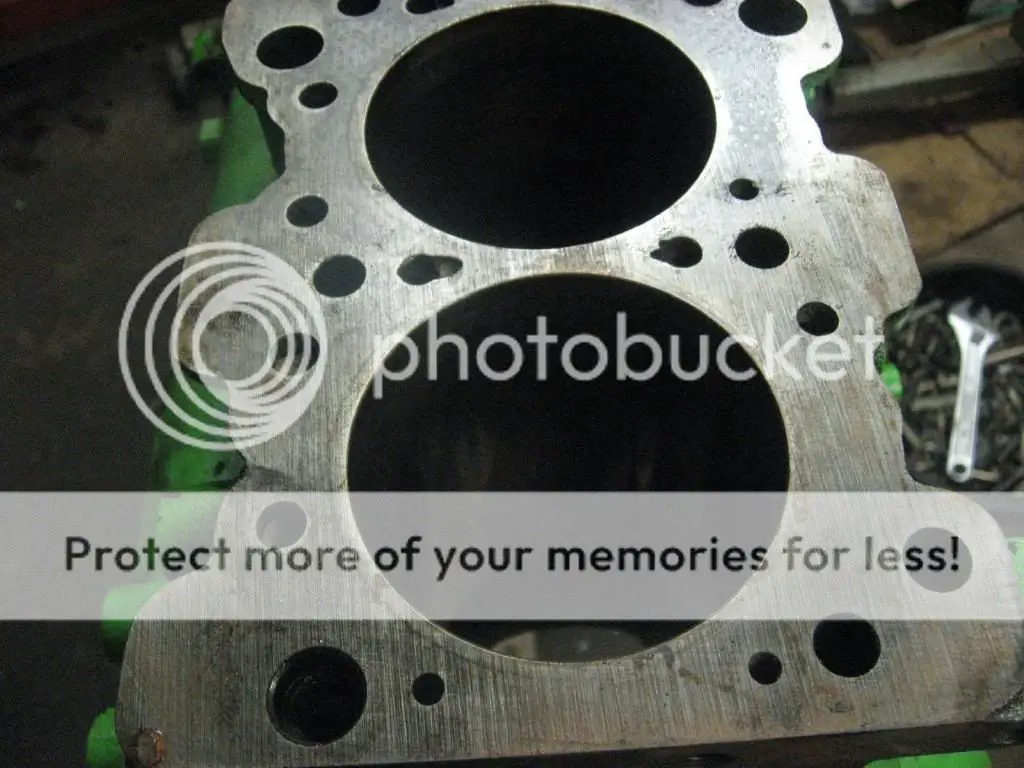

First thing I noticed is the block head gasket surface was belt surfaced.

A closer view.

Next I checked crank end play.

By hand I could move the crank appox .050

I mount the indicator and zero it.

Next with a pry bar I pull the crank forward and get .063 of crank movement.

Also the oil galley balls were not removed so the crank can be cleaned.

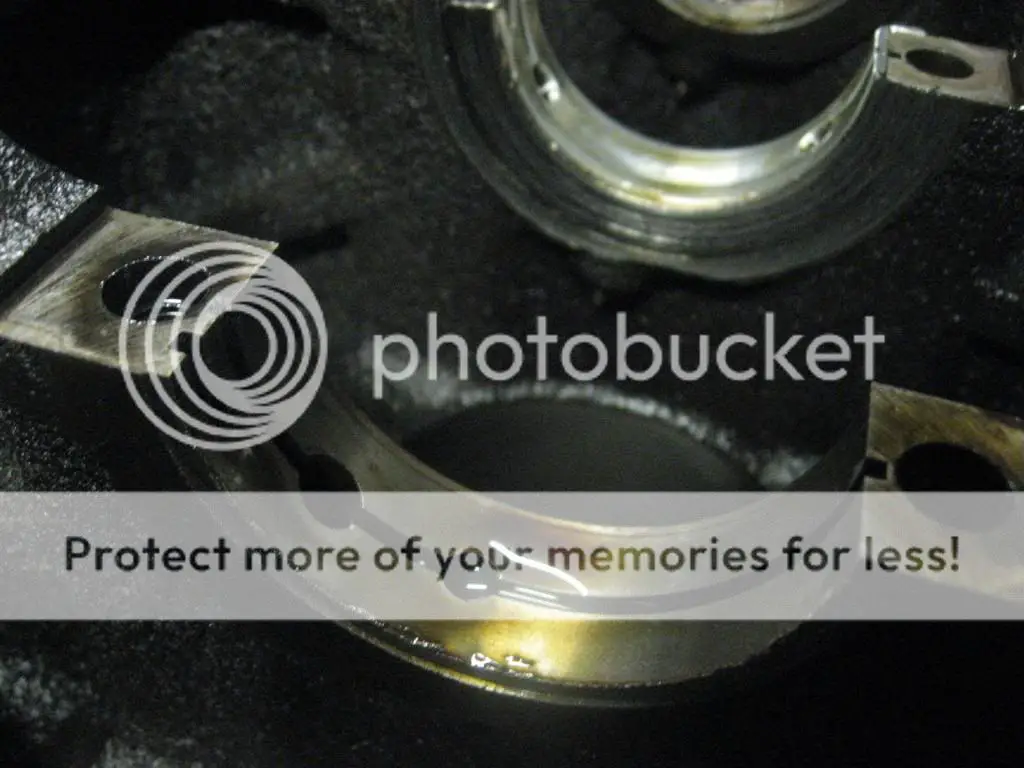

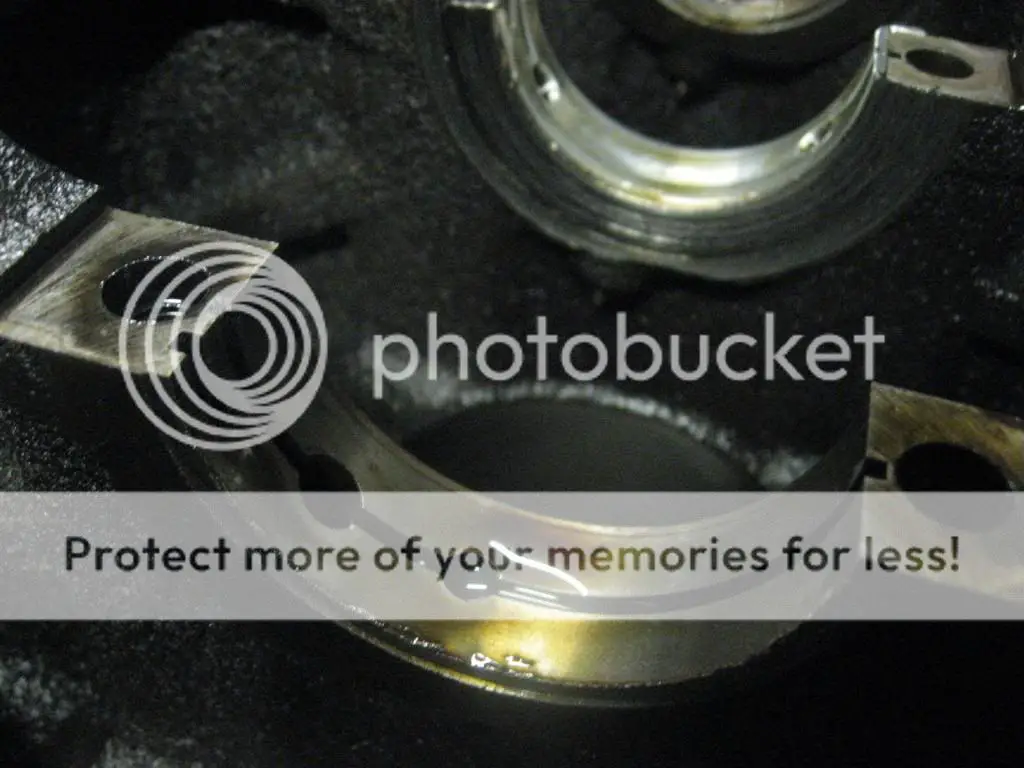

After removing the rod caps, I noticed that the bearings are showing copper in an odd wear pattern, this leads me to believe that the crank rod throw, or the rod housing bore is finished on a taper.

Also it looks like a fair amount of grit was in the oil.

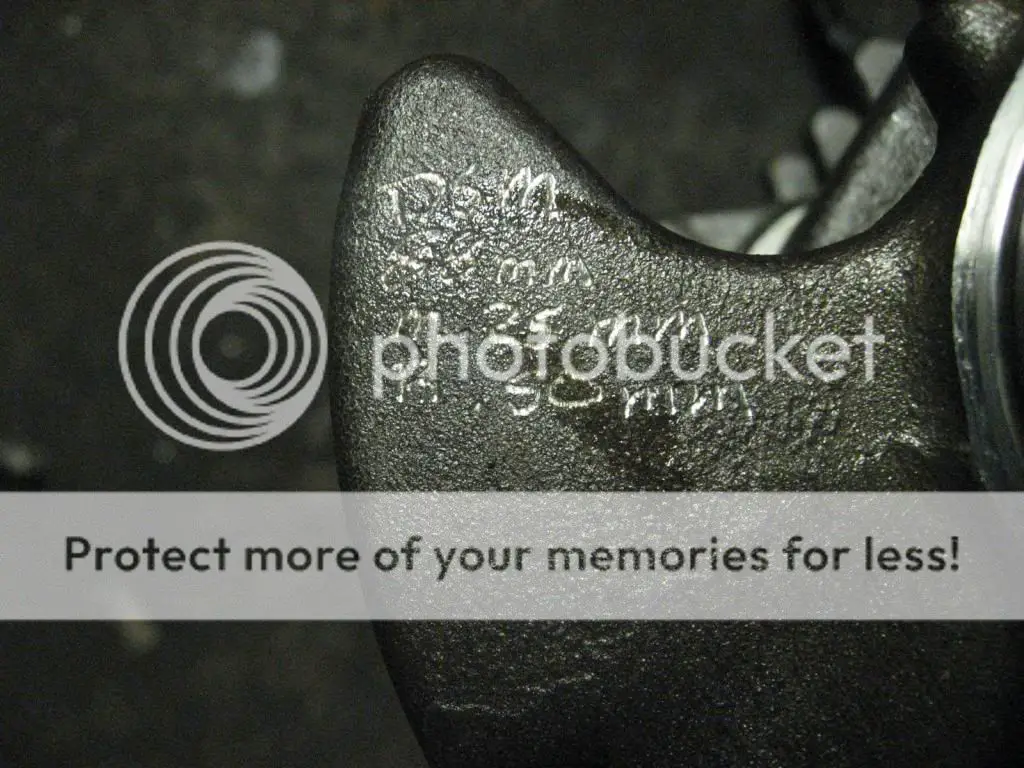

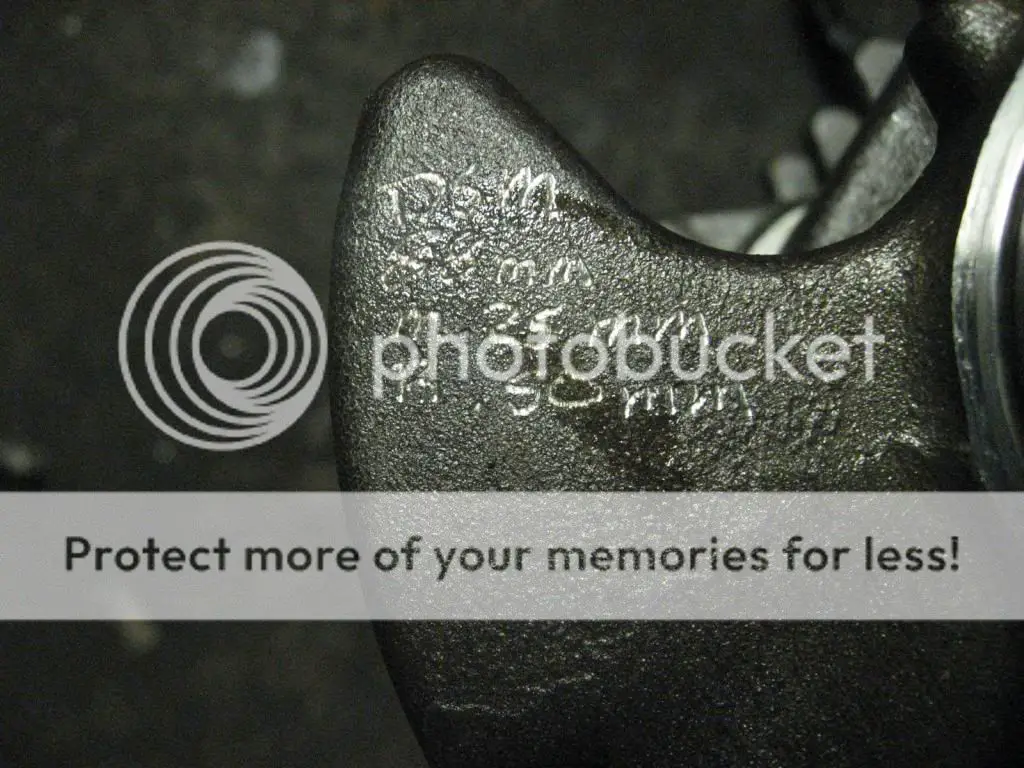

The crank was ground .25mm on the mains and .50mm on the rods. The etching on the crank shows this.

The bearings were marked and the correct sized bearings installed.

The wear on the rear thrust can be seen easily.

The crank is junk due to wear in the thrust face.

The 4th main got chewed into also from excessive crank end play.

So now the block is in the scrap pile.

The block had been bored .020 (.50mm) over and had evo pistons installed.

I measured the bores, and found 1 cyl .0005 tight, 2 of them were spot on, and the last was .0005 loose.

Next I measured one of the pistons and found it collapsed. The others were not measured at this time.

Not all the damage to this short block can be aimed at the machinist or the assembly of the engine. But the trash in the bearings, the taper to the rods or crank and the belt surfaced block can be, along with the inconsistent cylinder bores

The crank end play could be from an improper install of the girdle, or a heavy clutch.

There was a chunk of the oil pan gasket still on the block.

Once I removed the chunk of gasket, I found the machinist/assembler of this short block had signed his work.

7bolt 4g63T

I had this short block dropped off at my shop about 8 months ago as a core turn in. The story I was told was it had less than 2000 miles on it. It was shipped in from another machine shop that specializes in the 4g engine.

First thing I noticed is the block head gasket surface was belt surfaced.

A closer view.

Next I checked crank end play.

By hand I could move the crank appox .050

I mount the indicator and zero it.

Next with a pry bar I pull the crank forward and get .063 of crank movement.

Also the oil galley balls were not removed so the crank can be cleaned.

After removing the rod caps, I noticed that the bearings are showing copper in an odd wear pattern, this leads me to believe that the crank rod throw, or the rod housing bore is finished on a taper.

Also it looks like a fair amount of grit was in the oil.

The crank was ground .25mm on the mains and .50mm on the rods. The etching on the crank shows this.

The bearings were marked and the correct sized bearings installed.

The wear on the rear thrust can be seen easily.

The crank is junk due to wear in the thrust face.

The 4th main got chewed into also from excessive crank end play.

So now the block is in the scrap pile.

The block had been bored .020 (.50mm) over and had evo pistons installed.

I measured the bores, and found 1 cyl .0005 tight, 2 of them were spot on, and the last was .0005 loose.

Next I measured one of the pistons and found it collapsed. The others were not measured at this time.

Not all the damage to this short block can be aimed at the machinist or the assembly of the engine. But the trash in the bearings, the taper to the rods or crank and the belt surfaced block can be, along with the inconsistent cylinder bores

The crank end play could be from an improper install of the girdle, or a heavy clutch.

There was a chunk of the oil pan gasket still on the block.

Once I removed the chunk of gasket, I found the machinist/assembler of this short block had signed his work.