- Software Upgraded - Reset Your Password to Login

In order to log in after the forum software change, you need to reset your password. If you don't have access to the email address you used to register your GVR4.org account, you won't be able to reset your password. In that case, follow the instructions here to regain access to the forum.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GVR4_1057

Well-known member

I pulled one just like that out of 1604 in December. I attributed it to my clutch rod adjustment being way too tight and the ACT 2600.

mitsuturbo

Well-known member

say bi bi crankshaft!

IncorpoRatedX

Well-known member

ex GF crankwalked her 2g, looked just like that.

Thats crazy, you really think the crank is shot? the journal looks fine to me. There is some scraping on the counterbalance where it rides up against that bearing, but I haven't been able to really inspect it yet.

GVR4_1057

Well-known member

Mine wore a hell of a groove in the crank.If it cut through the bearing backing material that bad it had to do damage to the crank.

mitsuturbo

Well-known member

thrust area on the crank is shot, i guarantee it

IncorpoRatedX

Well-known member

+1 thrust side of that crank is likely torn up. spec it out.

that sucks didnt exactly budget in a crank when I took this thing apart /ubbthreads/images/graemlins/frown.gif. Ill definitely be sure is better before this thing goes back together though. Where can I find the specs to measure my crank and see if it is worn down or not?

Are they on VFAQ?

Are they on VFAQ?

Barnes

Well-known member

curtis

Well-known member

J-B must stand for Jon Barnes. /ubbthreads/images/graemlins/grin.gif

curtis

Well-known member

After looking at the first picture your cranks is probably toated. all the scratches on the bearing surface are probably from metal passing around. Sorry I been JSBing because of this very thing.

ApexHunter

Well-known member

Definitely want to check the fillet radius (where the journal meets the cheek). Spec for the these cranks is 3mm.

It's very critical for crank strength, often when a crank fails it fails on or very near the fillet radius.

Checking fillet radius, excerpted from here This is obviously a different engine, but it gives you the general idea.

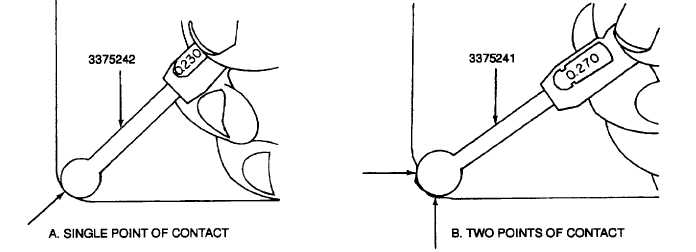

Check the fillet radii using fillet ball gages 3375241 and 3375242 as follows (see Figure 9-52):

(a) Place the 0.230 inch (5.84 mm) ball on the journal close to the fillet, and place a light behind the ball. One dark spot will be noted at the point of contact between the ball and the journal surface.

(b) Move the ball gage toward the fillet. If the fillet is properly blended, and at or above the minimum radius, only one point of contact should show as the ball contacts the fillet area and moves up to the bossing wall (A, Figure 9-52). If two points of contact show at any part of the radius, the radius is undersize.

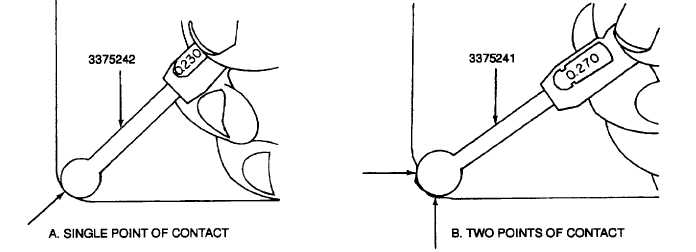

(c) Check the fillet with the 0.270 inch (6.86 mm) ball gage to ensure that it is not oversize. On this check two points of contact should show: one at the bottom and the other up on the side (B, Figure 9-52). If only one point of contact shows at any part of the radius, the radius is oversize.

(d) If fillet radius is incorrect, the grinding wheel was improperly dressed. Refer to step (2), above, for proper grinding wheel dressing

It's very critical for crank strength, often when a crank fails it fails on or very near the fillet radius.

Checking fillet radius, excerpted from here This is obviously a different engine, but it gives you the general idea.

Check the fillet radii using fillet ball gages 3375241 and 3375242 as follows (see Figure 9-52):

(a) Place the 0.230 inch (5.84 mm) ball on the journal close to the fillet, and place a light behind the ball. One dark spot will be noted at the point of contact between the ball and the journal surface.

(b) Move the ball gage toward the fillet. If the fillet is properly blended, and at or above the minimum radius, only one point of contact should show as the ball contacts the fillet area and moves up to the bossing wall (A, Figure 9-52). If two points of contact show at any part of the radius, the radius is undersize.

(c) Check the fillet with the 0.270 inch (6.86 mm) ball gage to ensure that it is not oversize. On this check two points of contact should show: one at the bottom and the other up on the side (B, Figure 9-52). If only one point of contact shows at any part of the radius, the radius is oversize.

(d) If fillet radius is incorrect, the grinding wheel was improperly dressed. Refer to step (2), above, for proper grinding wheel dressing

good information. Thanks. Ill try to get my hands of a set of fillet gauges, or maybe just that size and check it out. Just with the naked eye I can see that the thrust surface on the crank is no longer perfectly straight, but ill try to measure to confirm.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 8

- Views

- 2K