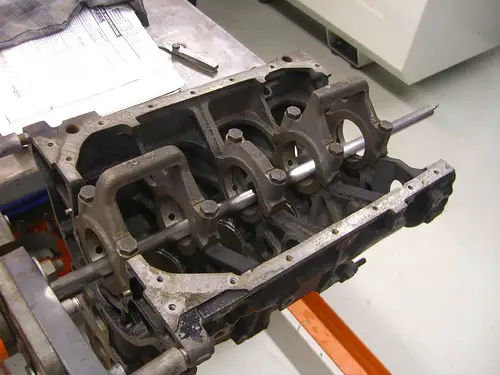

Good news and bad news. If you remember, block #1 got set aside when i found it was a NT block, and i did not feel confident enough to drill/tap for the oil squirters, as a slight error could cause major problems. Besides, i had another block as a backup, which was from a turbo car. The only downside to the spare being that it had already been bored/honed 0.50mm over before I bought it so I would not get to do that in class.

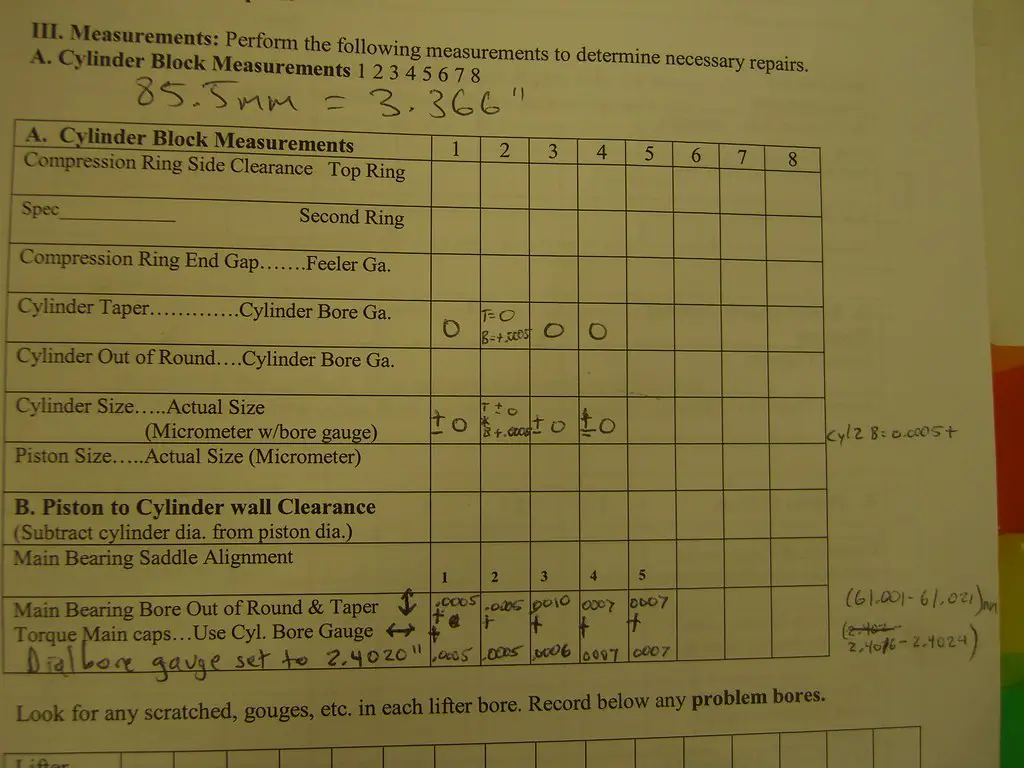

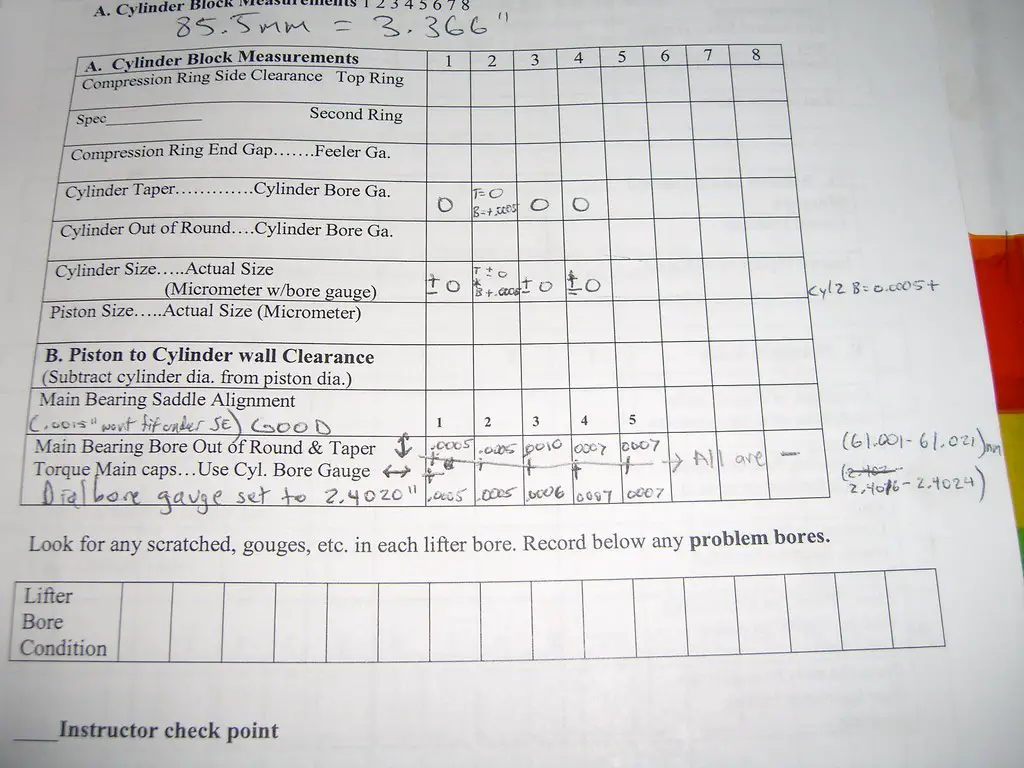

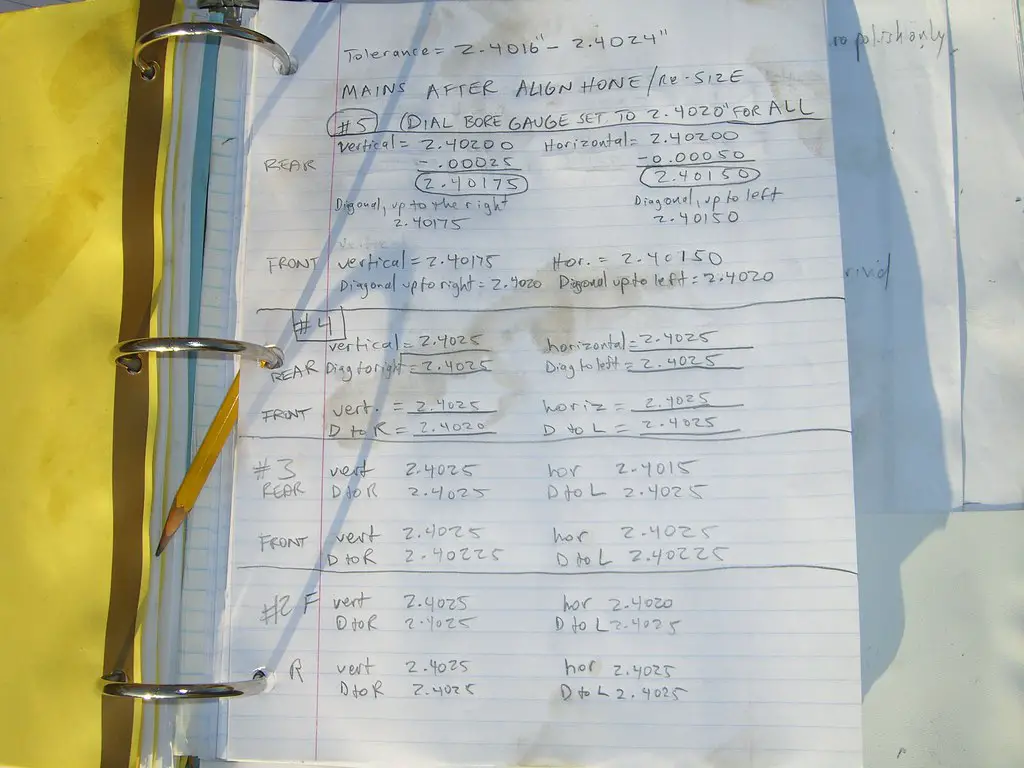

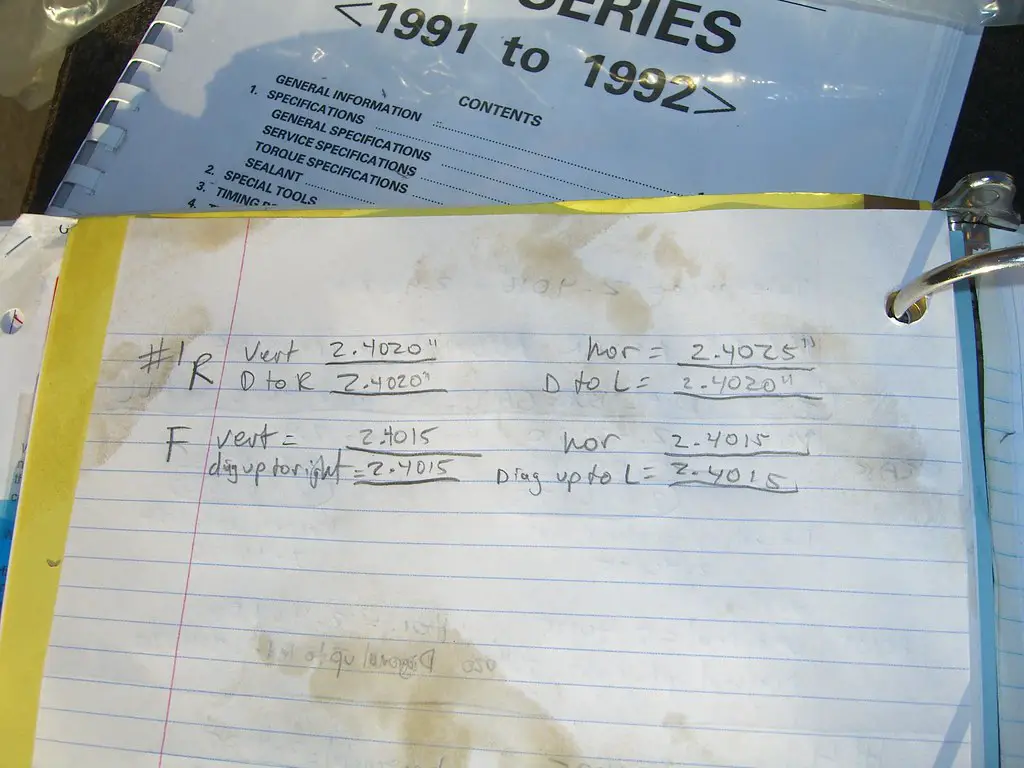

So here's the bad news. I measured the main bearing bores....and i'm out of range a little. Tolerance is 61.001-61.021mm, or 2.4016 or 2.4024". I set the dial bore gauge right in the middle, to 2.4020". Note that i used the .0005" dial bore gauge for this round of measurements, so everything between 0.0005" and 0.0010" i sort of guesstimated.

On Tuesday I’m gonna re measure the mains, this time using the ten thousandths dial bore gauge.

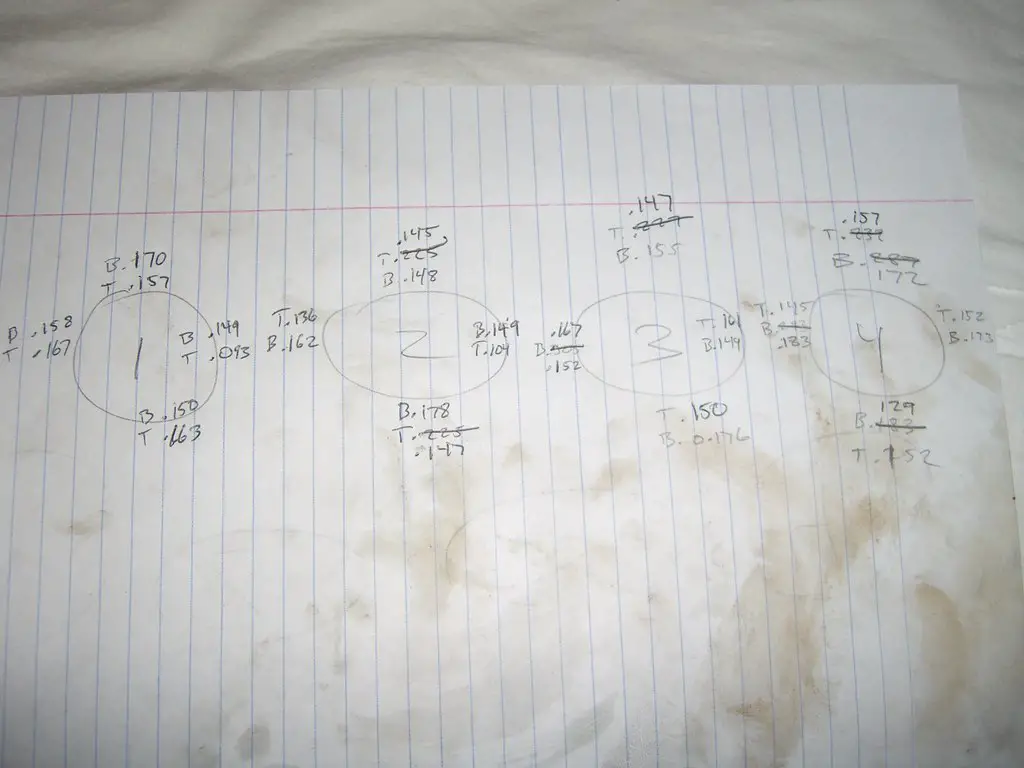

B= Bottom, T= Top (of bore).

Fortunately there is more good news than bad news.

The sonic testing results got the OK from the teacher, although the 0.093" on the back-top of cylinder 1 is marginal...he said it shouldn't be an issue, mainly due to the location.

I took the crank to EPWI for micropolishing...cost me $25 with the school's discount. /ubbthreads/images/graemlins/cool.gif I didn't get it re nitrided, because the "Building Max-Performance 4g63's" book says the factory nitriding goes ~0.020" deep, and EPWI confirmed this.

I might be getting a deal on some JE pistons through my boss. Will have to wait til SEMA is over to find out. My rods are currently still at L&B con rod service...they are all done, but i'm not gonna pick them up until i figure out what's going on with the JE's. L&B will be modifying them for use with full floating wrist pins if all goes well.

I was referred to a good shop to resize the mains.

The main saddles are in good alignment. I checked them with a straightedge today. I used a 0.0015" feeler gauge and a flashlight (looking for light under the straight edge).

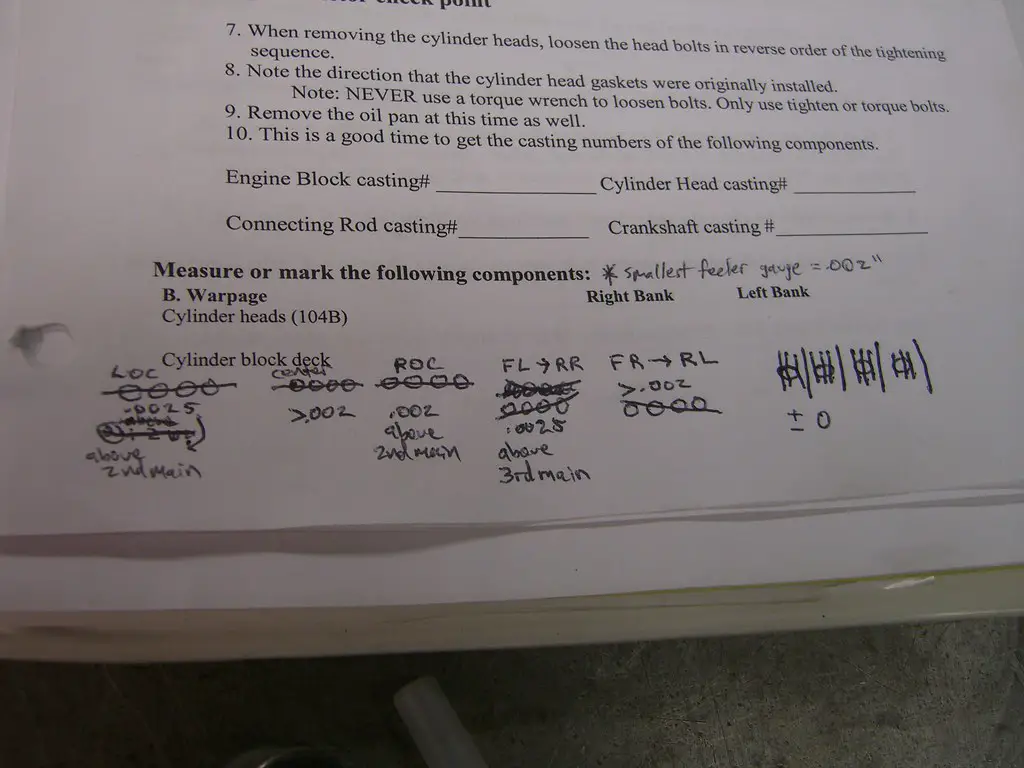

The deck only has slight warpage. Not an issue, i was planning on decking it slightly anyway to get a nice smooth surface for the MLS HG.

LOC= left of center, ROC= right of center. I also went straight down the middle lenghthwise on the block, diagonally both ways, and widthwise a bunch of times.

I feel like i'm forgetting something. It's late though so this is it. I have to work early.