Well, the third time is a charm. I dropped the motor in yesterday, and got it all buttoned up today. I have to say, with my current string of luck, I was crossing my fingers when I started it up for the first time. I hit the key and the motor fired right up.

I ran the car for about 3 minutes or so to check for oil leaks. Sure enough, I had a pretty heavy leak coming from the oil cooler line AN fittings right where they meet the OFH. I tried to tighten them up, but I guess the AN fittings have had it, because they were still leaking despite my attempts to fix them. The lines are -10 AN, and I couldn't source any fittings locally to replace the ones I have. As a result, I had to remove the B&M cooler, and am going to swap in the OEM cooler from my 90 GST donor car for the time being. The -10 AN lines were such a pain in the ass to manipulate because they are so rigid and stiff, that I'm switching to -8 AN when I replace them.

I also got my Innovate LC-1 wideband installed and calibrated. I fired up the car and set my V3 to log the wideband on the EGR input. It seems to be working good, and I'm excited to start playing with my tune a little bit now that I have something to go off of.

Besides my oil leak, the car seems to run great. It seems like the valve train is a little noisy. I'm not sure if it's because I didn't really run the car for long enough to get it up to temp, or if the head was just a little dry from sitting for so long? I'm wondering if the larger cams are contributing to this also? Do you guys running aftermarket cams notice a little extra valve train noise over stock? Anyways, here are a few pics of the finished product.

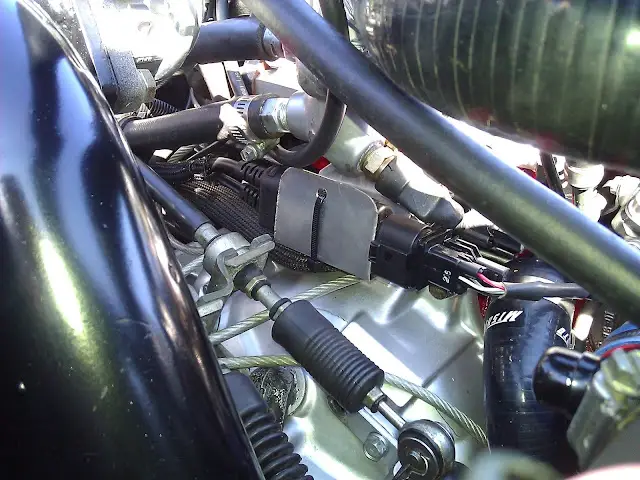

Here's where I relocated the coil pack to. The coil is easily accessible here, but also gives the engine bay a clean look.

I replaced the injector clips with the quick disconnect type, and tucked the harness around the fuel rail. This made for a great finish.

I built a custom bracket to keep my LC-1 all safe and sound. The bracket should also act as heat barrier as well.

Here are a few electrical tid bits. I fabricated the black cover, which holds a NRG Voltage Stabilizer E-PAC3, and a digital voltage readout. On the side is a custom grounding kit made of 8GA wire, each of which is attached to a trans mounting bolt. All of the wires spider back to the distribution block in the photo, which is then tied into the voltage stabilizer, battery ground, and chassis ground. Eventually, I'm going to run a 12GA wire straight from the charging post on the alternator to the positive battery terminal. The factory wire is too small IMO.

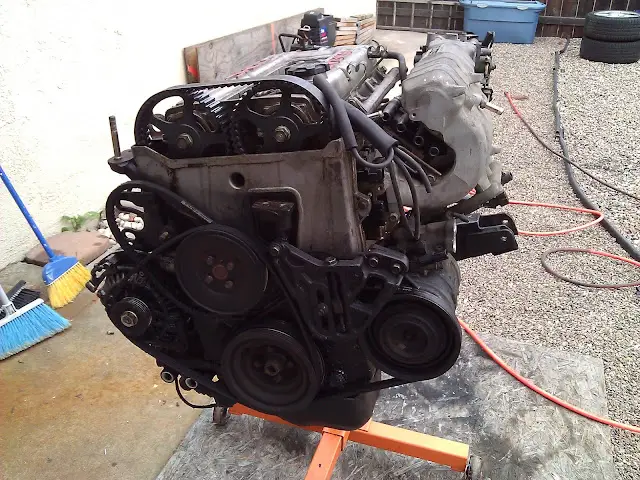

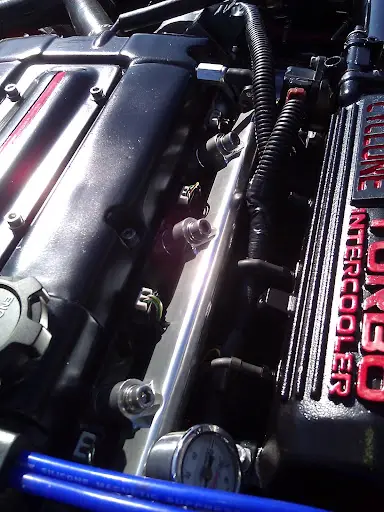

Zaklee Corp timing belt cover, Aeromotive FPR, Avid aluminum mounts, AEM tru-time cam gears, HKS 264/273 cams and a cyclone intake manifold.

Aluminum radiator, OEM Mitsu thermostat, Mishimoto upper and lower radiator hoses, dual Mishimoto 10" slim fans and shroud, OBX -6 AN fuel rail with new O-rings, Russell fuel filter, black top CAS and Innovate LC-1 wideband O2.

2G MAS, new K&N 4" filter, Dejon intake pipe

Out with the clock, in with the Innovate wideband and auto timer display.

A USDM smile.

I should have the oil cooler mounted up and installed tomorrow, and then when I'm satisfied there are no more oil leaks it's off for a test drive!