^^^Yeah Mike that was a pretty sweet meet. I really like the wine colored 1G next to mine, I always thought that was such a nice color on the first gen cars. Hopefully I get the VR4 in on the action next time!

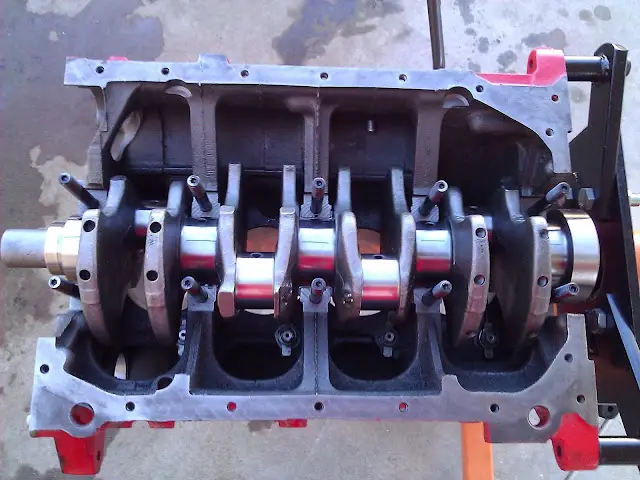

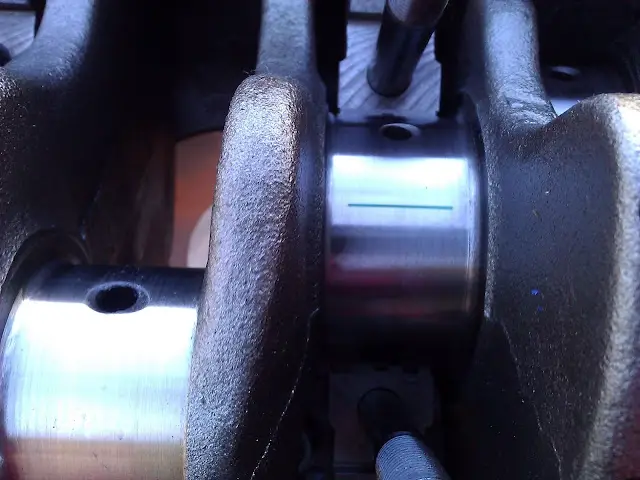

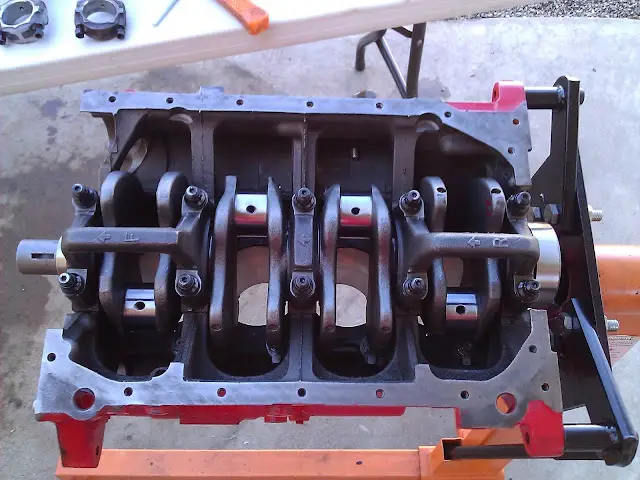

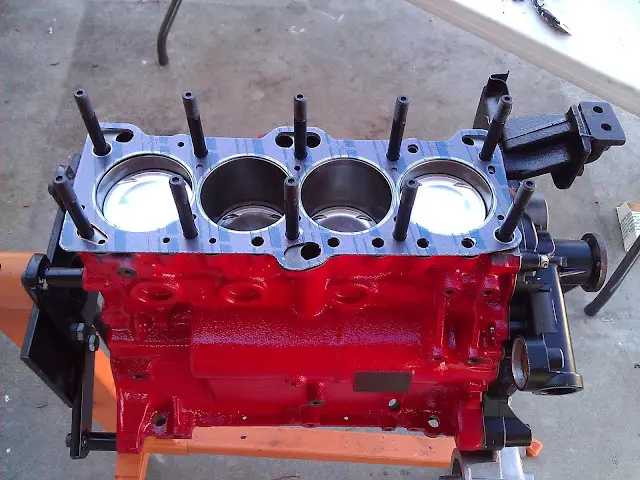

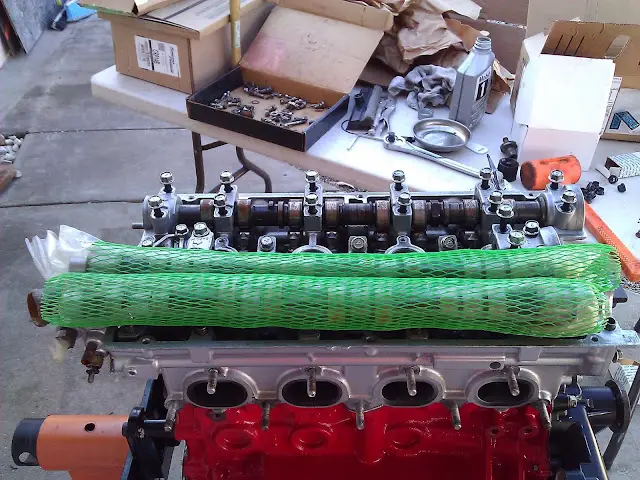

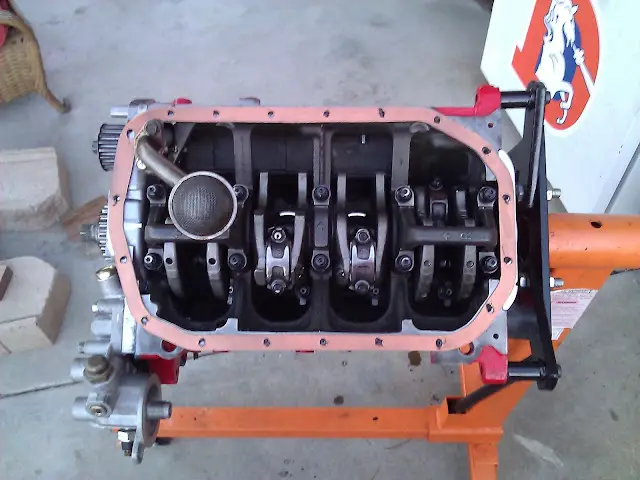

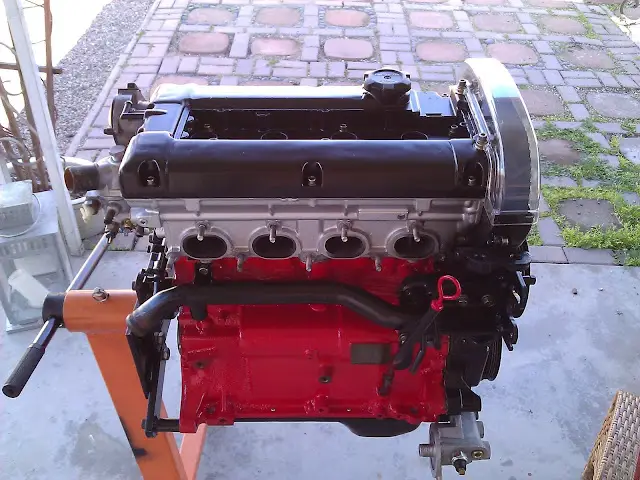

Speaking of getting the VR4 back in action, I got to make a little progress today. I got my replacement rod back from the machine shop, and could finally balance all the rotating components. I washed everything, and removed all the dirt and carbon form the pistons. I weighed the wist pins and pistons, all of which weighed exactly the same. It appears Ross makes a very refined product. Next, I assembled the rods and weight matched the little ends. After that, I weighed the whole rod and weight matched them once again, this time removing material from the big end. The only difficult part of this process is matching the little end weight of the rods, while at the same time maintaining the overall rod weight. For instance, I would have one rod with a little end that was a few grams to heavy. I would then remove some material from the small end, but by doing so the overall weight would be off a little. It's a delicate balance that takes some practice to get the hang of, but it is much easier than it sounds. It's not hard, but a time consuming process of taking off material, weighing the rod, then rinse and repeat time and time again until it is absolutely perfect. I didn't have a belt sander to remove material like most machine shops do, but an angle grinder worked just fine. I just took my time, removed metal evenly and polished each rod with some sand paper at the end to give each rod a nice finish. End result was