You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

504/2000 Restoration project and 2 other VR4. Why do I love these cars!!

- Thread starter bobdole

- Start date

What did your process look like to get it from rusty bucket to this immaculate state tools,supplies process etc very impressive.

I started by pressure washing the undercarriage and cleaning with Simple Green. Then did some heavy sanding. I also used a wire brush and a wire wheel. Then did 2 coats of Rust Bullet and covered with rubberized undercoating. I replaced alot of parts. I also had alot of parts sand plasted and powder coated.

Quoting bobdole:

I started by pressure washing the undercarriage and cleaning with Simple Green. Then did some heavy sanding. I also used a wire brush and a wire wheel. Then did 2 coats of Rust Bullet and covered with rubberized undercoating. I replaced alot of parts. I also had alot of parts sand plasted and powder coated.

Thanks I think I will be trying to get some of this done soon on my car its not too bad but winter will be here soon..

I started by pressure washing the undercarriage and cleaning with Simple Green. Then did some heavy sanding. I also used a wire brush and a wire wheel. Then did 2 coats of Rust Bullet and covered with rubberized undercoating. I replaced alot of parts. I also had alot of parts sand plasted and powder coated.

Thanks I think I will be trying to get some of this done soon on my car its not too bad but winter will be here soon..

Last edited by a moderator:

Romanova

Well-known member

I love this thread! /ubbthreads/images/graemlins/cool.gif

Update:

Got more parts in from Mitsubishi.

Brake dust shields, New Rad hoses and gaskets for the front bumper lights.

Worked more on the welding:

Also took of the side skirts to check for more rust and they look great. So should be good.

Once the welding is complete then I can paint with the Rust Bullet and undercoat.

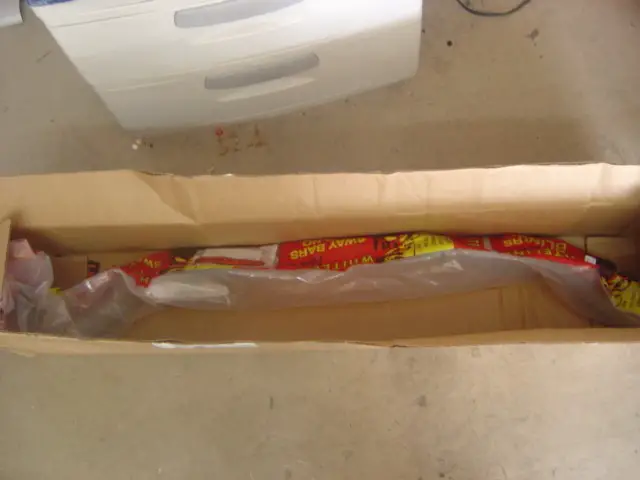

Also the sways are on there way. So I can put the rear suspension back up.

Got more parts in from Mitsubishi.

Brake dust shields, New Rad hoses and gaskets for the front bumper lights.

Worked more on the welding:

Also took of the side skirts to check for more rust and they look great. So should be good.

Once the welding is complete then I can paint with the Rust Bullet and undercoat.

Also the sways are on there way. So I can put the rear suspension back up.

Last edited:

Whoodoo

Well-known member

You should really be cleaning more before you weld. Weld on rust, you get rust in the weld and no matter how much rust bullet you put on there, it will still be there. This means it will rust out sooner in that same spot. How soon is another question, but it will happen.

Good on you for getting your hands dirty though

Good on you for getting your hands dirty though

SouthCaliVR4

Well-known member

I have used a product called rust mort. Auto paint store's can get order it or it may be available online these days. This can be thinned with water & sprayed into cavities to stop rust & leave a protective coating that will stop it from rusting further. I have used it with great success when replacing panels & wanting to protect the backsides of welds I didn't have good access to. My method was to thin according to directions then use a garden sprayer on wide mist to get back into tight spots & blind cavities. Use it to excess & the metal will not rot from the inside out.

Great job so far Mr. Dole. /ubbthreads/images/graemlins/cool.gif That was some exhuast leak. /ubbthreads/images/graemlins/ooo.gif

Quoting Whoodoo:

You should really be cleaning more before you weld. Weld on rust, you get rust in the weld and no matter how much rust bullet you put on there, it will still be there. This means it will rust out sooner in that same spot. How soon is another question, but it will happen.

Good on you for getting your hands dirty though

I cut back until it was solid metal. Didn't weld on rust. Also it was a tough job welding in that location.

You should really be cleaning more before you weld. Weld on rust, you get rust in the weld and no matter how much rust bullet you put on there, it will still be there. This means it will rust out sooner in that same spot. How soon is another question, but it will happen.

Good on you for getting your hands dirty though

I cut back until it was solid metal. Didn't weld on rust. Also it was a tough job welding in that location.

Whoodoo

Well-known member

I hear ya, welding in awkward places is a real pain. However, even just the slightest bit of contaminant getting into your weld will cause more metal to oxidize, so you need to have everything absolutely clean before you start.

For my senior project, my group designed and built a log splitter. For a stronger blade on the wedge, I built up weld beads and then ground it down. Before I started, I didn't get the two pieces of steel making up the V clean enough and it made the biggest headache of all time. The first bead I ran got contaminated, then I was chasing it around layer after layer. Often times it got so bad I had to grind it all off and hopefully find a clean layer to start on again.

Welding is like painting in that, in order to get a good finished product you need to prep well.

Regardless, I have a lot of respect for you for doing it yourself. I'm sure having good solid metal there is a huge improvement over what it was. /ubbthreads/images/graemlins/applause.gif

For my senior project, my group designed and built a log splitter. For a stronger blade on the wedge, I built up weld beads and then ground it down. Before I started, I didn't get the two pieces of steel making up the V clean enough and it made the biggest headache of all time. The first bead I ran got contaminated, then I was chasing it around layer after layer. Often times it got so bad I had to grind it all off and hopefully find a clean layer to start on again.

Welding is like painting in that, in order to get a good finished product you need to prep well.

Regardless, I have a lot of respect for you for doing it yourself. I'm sure having good solid metal there is a huge improvement over what it was. /ubbthreads/images/graemlins/applause.gif

Thanks Whoodoo. I will keep my eye on that area. Check it from time to time. This is my first time dealing with rust. I won't buy a car again with out seeing it in person. Lesson learned. But I am enjoying working on the car. But I don't think it is that bad compared to other cars I have seen.