So first off I got tired of this sh*t

So I finished the catback

It got really, really quiet... kinda nice but I may take it off for track days when Im feelin froggy.

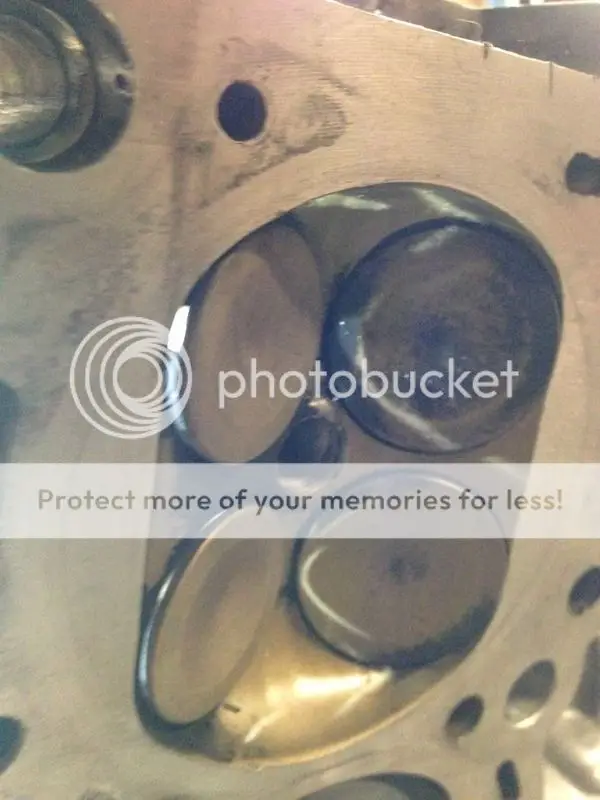

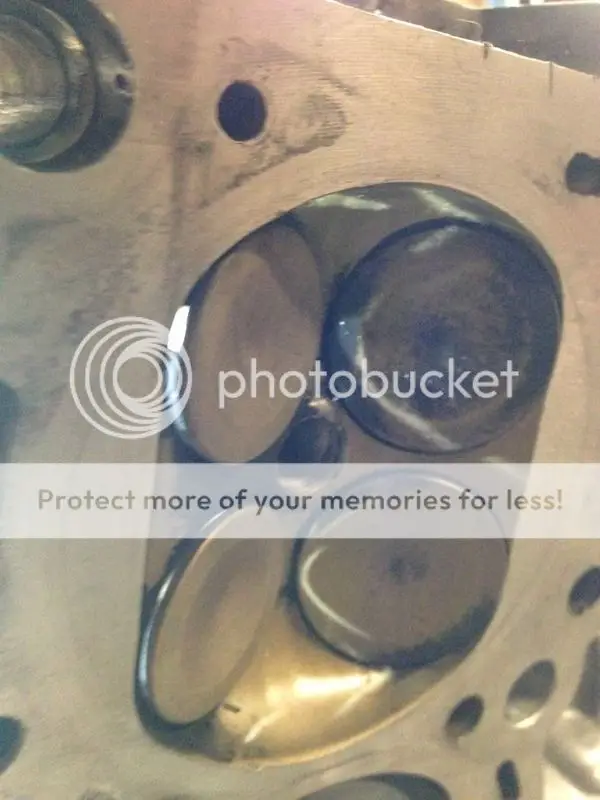

Then I was seeing some uneven compression/starting. Compression was 160/160/55/60 and it was all going out the valves, so I pulled the head without really looking into it.

It was due to the lifters being pumped up rock solid.

With the cams backed down they hold great.

I sent the head to check valve installed height, it was on the money at 1.92, I compared a ton of things with a stock head/cams/valves and everything looks fine. The 3G HLAs ride .030 open at the base circle, same as stock, they were cleaned/bled down when they were installed like always so Im pretty clueless. I talked to Kiggly and he said his HLA regulator would not solve this issue, that he had only seen this when the HLAs were bottomed out on a big base circle cam. I put in some 2G HLAs to try those, along with getting a damn oil pressure gauge in the car. I know I shouldve had one just needed to do it. My thoughts at this point on the pumped up HLAs are its either that much oil pressure overcoming the springs, or Im floating valves letting them extend more than base circle. The latter doesnt seem very likely cause even driving to the shop to pull the head the car pulls great, smooth, definitely on all 4. The shady compression numbers and such are just during cranking and idle, after that it smooths right out. I dunno I will monitor oil pressure and go from there.

Did the gauge pod install in the glove box like I wanted. My buddy 3D printed them out

Then I got to work on the next step on the car, a real manifold. I dont know how much itll actually help so just kind of doing it for the data more than anything. First was port matching the flanges

and cutting up these merge collectors

and working the reducers in. **DISCLAIMER, I do not TIG. These tacks are me mocking it up with stainless rod or just fusing without any filler, so my buddy who does TIG can weld them right. I asked if I could just MIG them together and he didnt want it contaminated with anything but stainless. It holds together and thats all Im trying to do here.

The original plan was to run the same 12cm housing, at the same turbo position to save from changing the downpipe or anything, but with hearing people running 18+cm housings and spooling earlier than I am I think I will go ahead and move the turbo out a little, this 12cm barely clears and I did check that a 14cm would hit. My thoughts were people can run the BEP 9cm and hit mid 600s so why wouldnt a 12 be okay, but all the twin scroll guys say I will be restricted. The main reason for wanting to keep the same turbo position, besides less work, is I wanted a back to back dyno test of them! Nobody out there has done one that Ive seen and the results are way too hearsay. We will see how that one works out, I will do my best to get some info out there for the community when I dyno the car, which my buddy really wants me to come and do.

So the status on the car now is I now have 70 miles on the engine running 15 psi and tuning everything in, the car pulls much better in the high RPMs (Ive only taken it to 8k so far) and Im seeing the same 50-70mph times as when I was running 21 psi on the last setup. I feel like if I could get in the mid 20s of boost I could be as fast on pump as I was last year on E85 which would be pretty amazing. Thats all for now thanks for reading.