Hey guys, I don't post here very much but I wanted to fill you all in on the G-VR4 build that I have taken on with the help of my older brother Alex from DSG and the entire shop really. My name is Nick and I'm one of Alex's younger brothers, (the youngest). Id first like to publicly thank Alex for all his help as I would not have gotten nearly as much done as I have, or should I say as We have.

I'll start with the pick up. Alex and I drove up to Vermont to pick up #300/2000 from a good friend of Alex's. This gentleman is an engineer and had hopes of doing ice races in this Galant. He had spent a lot of money getting into shape with things like a TRE transmission, a big 16G turbo, a Spearco front mount, external oil cooler, solid poly bushings throughout, SS braided lines on all hydraulic lines, clutch and brake, rear steering delete with a TSi LSD rear end, ABS delete, Galant RS motor with the balance shafts removed, 2g MAF, an SAFC, 16x7 Sparco Rally wheels, H&R springs, (I think) with AGX struts (soon to be gone), and a bunch of other stuff I'm sure to be forgetting.

So the rest was up to me. We picked up the car in beginning of November and pulled in all the way back to the DSG shop to being the heavy diet I planned on assign it. I know these cars are quite portly from the factory, and luckily mine was already missing the rear seats and most of the interior, including the entire carpet. The only things remaining where the roof liner, the dash, both front seats, the front seat belts, and the door panels.

The engine bay had some interesting colors that look like they were the result of a 4 year old with a box of crayola crayons. Nothing really matched and everything that was painted was chipping a rusted.

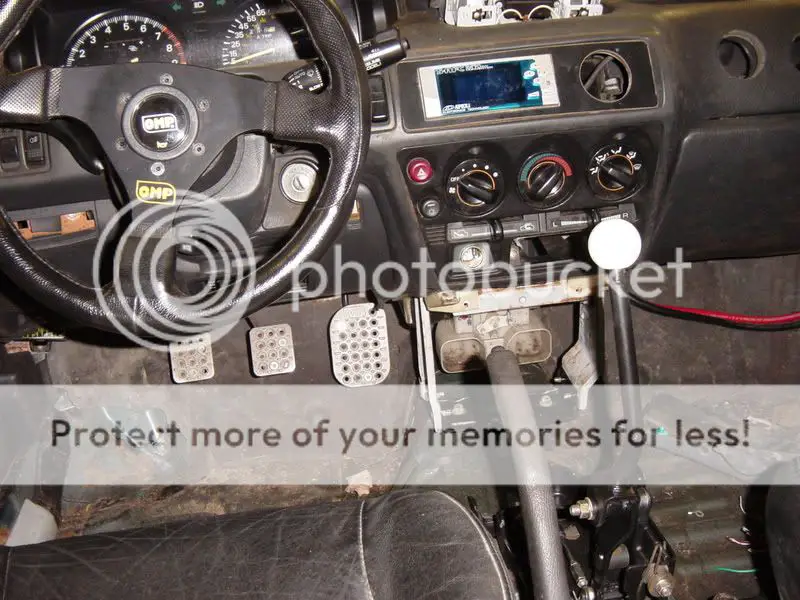

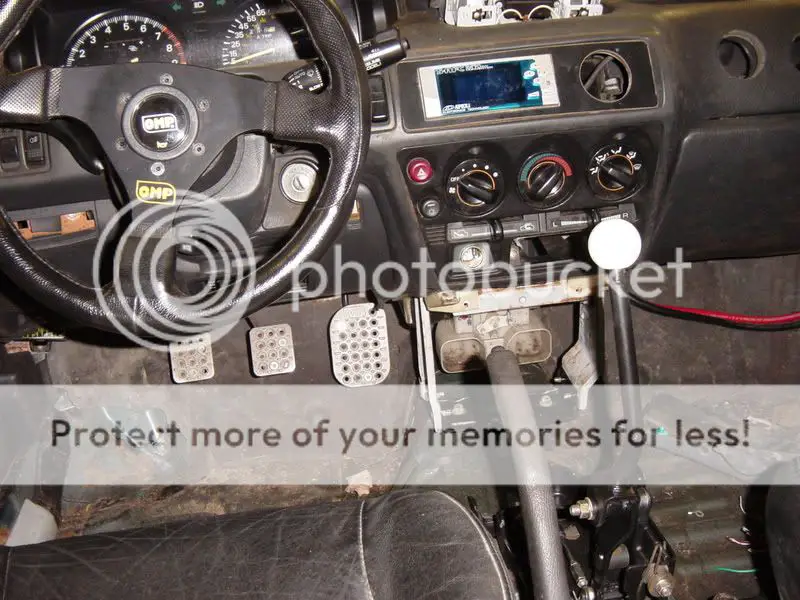

The shifter was one of the first things I decided to fix. The windshield was leaking across the top, (something I discovered later), so the shifter was incredibly rusted. After a few minutes with the media blaster and a couple more in the hand of Master Fabricator/Engineer Alex, I had a customer short shifter with long rod and super short throw.

As the paint was drying on the shifter, I tackled the valve cover. A hour or so of sanding and a few minutes in the parts washer got most of the ugly blue paint off.

I chose a dark grey hammered paint, actually the same stuff that Alex used on the EVOII.

Other notables in the pics above are the painted intake manifold and custom DSG heat shield for the turbo. The engine bay continues to change as the project continues, you will see as the pics progress.

The oil pan was pretty badly dented, as if someone had jacked the car up by it. . . So it was removed, along with all the sub frame rails and was pounded back into shape. I felt better having done that, as the oil capacity was probably increase by half a quart or so. Before re-installing everything, it all gets a healthy coat of black POR-15 paint.

As I said before, the car was put on a major diet, and we attacked the heaviest parts first. The bumper supports.

The only thing remaining on the rear bumper is the cover and the 2 mounting points that protrude under the trunk. The entire support has been removed. And in the front, much the same:

As I had said before, the windshield was leaking pretty badly. This, plus the fact that a family of rodents was calling it home while it resided in VT, was causing a foul musky mildew odor to linger about the interior. Getting the nesting out of the heater box was the very first thing I did to the car, but the water leak was a bit more involved. We removed the windshield we resealed it with window weld.

Alex then helped to tidy the engine bay. He cleaned up the intercooler piping a bit from this:

To this:

There is more work to be done. As of now they are all stacked up and rubbing against each other. Once properly massaged they will all fit snuggly, but without contact. The BOV, by-pass valve, what-ever-you-want-call-it has been clocked 90 degrees so it diverts air back into the intake piping also. I plan on sending all the new piping out for anodizing soon, I'm thinking gold to match the wheels. /ubbthreads/images/graemlins/laugh.gif

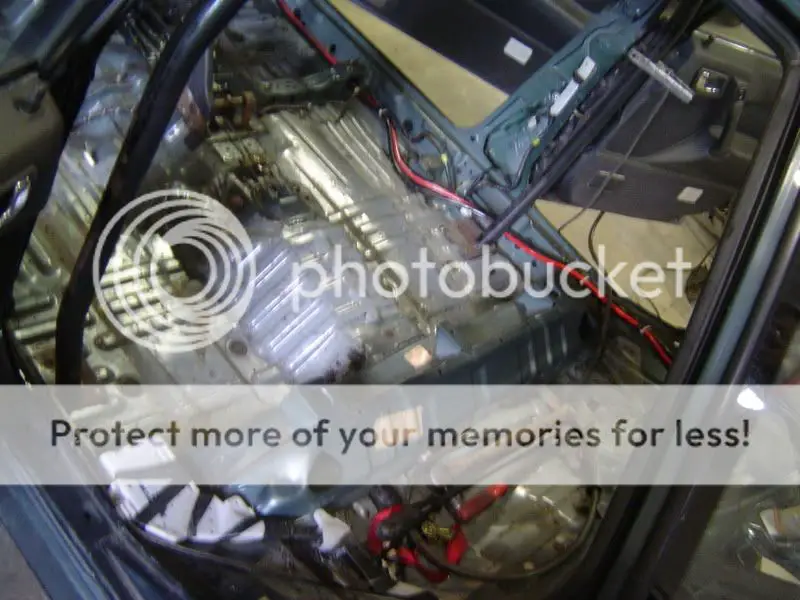

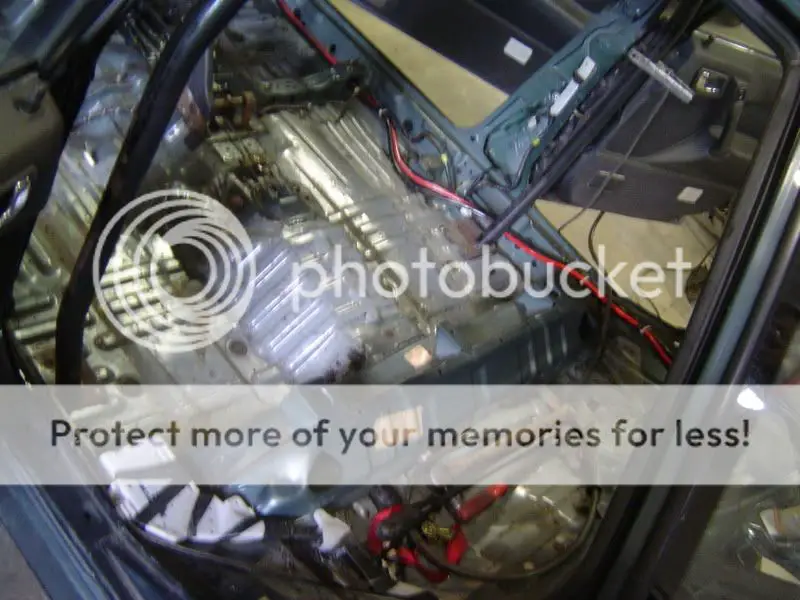

The work on the interior continued; the carpet was out, but the sound deadening remained. And in order to get down to a fighting weight, it had to come out. (Also so we could get the roll bar in)

So it went from this:

To this:

I was advised to use a bit of dry ice and freeze the tar paper before trying to remove it. But luckily for me, it was brittle enough for me to use the air hammer and a chisel bit. 2 hours later, the entire floor was striped. (And my ears were ringing for another 2 hours after wards.)

You'll notice that the roll bar was just placed in the pic above. It was sourced from Garfield on this board, who Id like to thank again for his efforts while figuring out the shipping issues we faced.

Alex and I have since welded the entire cage in, with the exception of the passenger side harness bar, (we ran out of tubing).

The cage was from a Galant RS, so it really fit perfectly. The only issue was that the main hoop was lined up with the B pillar, and didn't allow for a proper harness bar to be fitted. So we chopped about 6in off the rear mounts to move the hoop back for the harness bars.

Once moving it back, the rear doors would not fully close. So the rear door panels had to be removed. It was tight fit, but it fits none-the-less.

Thanks Al. I feel much safer.

The stock seats will simply not due for what I have planned for the car. They may be nicely suited for cruising the town with their supple leather and multiple ergonomic adjustments; but for racing, they are heavy and do not provide the proper support and comfort needed. So I bought 2 Sparco Sprint seats instead. I wanted black, none were in

stock, so I settled for red.

After Alex fabbed up some seat brackets and the seating logistics were sorted, I was able to sand and paint the entire floor of the car with POR-15, (I love this stuff)

So the interior is really coming together. And the remaining tubing is in the mail. I bought some 5 point harnesses that will be installed after the passenger side harness bar is in, and then I'll finish painting the cage and the rest of the interior.

The next step is the exterior. It currently sits Belize green with all 16 years showing on the paint. The front bumper is in the worst shape, and will need the most attention. Ive thought about this for a long time and after discussing it with the rest of the DSG guys Ive decided on white. Al's EVO is white, Bill's 240 Maxi is white, the STi will be

white, as so will mine.

And just so I could get an idea of how it will look, I did a few photochops:

We also discussed a two-tone job, and an all black paint job.

There will be many more pics to come as work continues. All questions, comments, suggestions and concerns are welcome. I am new to the DSM world, but a self proclaimed "Vet" of the Honda nation.

I'll start with the pick up. Alex and I drove up to Vermont to pick up #300/2000 from a good friend of Alex's. This gentleman is an engineer and had hopes of doing ice races in this Galant. He had spent a lot of money getting into shape with things like a TRE transmission, a big 16G turbo, a Spearco front mount, external oil cooler, solid poly bushings throughout, SS braided lines on all hydraulic lines, clutch and brake, rear steering delete with a TSi LSD rear end, ABS delete, Galant RS motor with the balance shafts removed, 2g MAF, an SAFC, 16x7 Sparco Rally wheels, H&R springs, (I think) with AGX struts (soon to be gone), and a bunch of other stuff I'm sure to be forgetting.

So the rest was up to me. We picked up the car in beginning of November and pulled in all the way back to the DSG shop to being the heavy diet I planned on assign it. I know these cars are quite portly from the factory, and luckily mine was already missing the rear seats and most of the interior, including the entire carpet. The only things remaining where the roof liner, the dash, both front seats, the front seat belts, and the door panels.

The engine bay had some interesting colors that look like they were the result of a 4 year old with a box of crayola crayons. Nothing really matched and everything that was painted was chipping a rusted.

The shifter was one of the first things I decided to fix. The windshield was leaking across the top, (something I discovered later), so the shifter was incredibly rusted. After a few minutes with the media blaster and a couple more in the hand of Master Fabricator/Engineer Alex, I had a customer short shifter with long rod and super short throw.

As the paint was drying on the shifter, I tackled the valve cover. A hour or so of sanding and a few minutes in the parts washer got most of the ugly blue paint off.

I chose a dark grey hammered paint, actually the same stuff that Alex used on the EVOII.

Other notables in the pics above are the painted intake manifold and custom DSG heat shield for the turbo. The engine bay continues to change as the project continues, you will see as the pics progress.

The oil pan was pretty badly dented, as if someone had jacked the car up by it. . . So it was removed, along with all the sub frame rails and was pounded back into shape. I felt better having done that, as the oil capacity was probably increase by half a quart or so. Before re-installing everything, it all gets a healthy coat of black POR-15 paint.

As I said before, the car was put on a major diet, and we attacked the heaviest parts first. The bumper supports.

The only thing remaining on the rear bumper is the cover and the 2 mounting points that protrude under the trunk. The entire support has been removed. And in the front, much the same:

As I had said before, the windshield was leaking pretty badly. This, plus the fact that a family of rodents was calling it home while it resided in VT, was causing a foul musky mildew odor to linger about the interior. Getting the nesting out of the heater box was the very first thing I did to the car, but the water leak was a bit more involved. We removed the windshield we resealed it with window weld.

Alex then helped to tidy the engine bay. He cleaned up the intercooler piping a bit from this:

To this:

There is more work to be done. As of now they are all stacked up and rubbing against each other. Once properly massaged they will all fit snuggly, but without contact. The BOV, by-pass valve, what-ever-you-want-call-it has been clocked 90 degrees so it diverts air back into the intake piping also. I plan on sending all the new piping out for anodizing soon, I'm thinking gold to match the wheels. /ubbthreads/images/graemlins/laugh.gif

The work on the interior continued; the carpet was out, but the sound deadening remained. And in order to get down to a fighting weight, it had to come out. (Also so we could get the roll bar in)

So it went from this:

To this:

I was advised to use a bit of dry ice and freeze the tar paper before trying to remove it. But luckily for me, it was brittle enough for me to use the air hammer and a chisel bit. 2 hours later, the entire floor was striped. (And my ears were ringing for another 2 hours after wards.)

You'll notice that the roll bar was just placed in the pic above. It was sourced from Garfield on this board, who Id like to thank again for his efforts while figuring out the shipping issues we faced.

Alex and I have since welded the entire cage in, with the exception of the passenger side harness bar, (we ran out of tubing).

The cage was from a Galant RS, so it really fit perfectly. The only issue was that the main hoop was lined up with the B pillar, and didn't allow for a proper harness bar to be fitted. So we chopped about 6in off the rear mounts to move the hoop back for the harness bars.

Once moving it back, the rear doors would not fully close. So the rear door panels had to be removed. It was tight fit, but it fits none-the-less.

Thanks Al. I feel much safer.

The stock seats will simply not due for what I have planned for the car. They may be nicely suited for cruising the town with their supple leather and multiple ergonomic adjustments; but for racing, they are heavy and do not provide the proper support and comfort needed. So I bought 2 Sparco Sprint seats instead. I wanted black, none were in

stock, so I settled for red.

After Alex fabbed up some seat brackets and the seating logistics were sorted, I was able to sand and paint the entire floor of the car with POR-15, (I love this stuff)

So the interior is really coming together. And the remaining tubing is in the mail. I bought some 5 point harnesses that will be installed after the passenger side harness bar is in, and then I'll finish painting the cage and the rest of the interior.

The next step is the exterior. It currently sits Belize green with all 16 years showing on the paint. The front bumper is in the worst shape, and will need the most attention. Ive thought about this for a long time and after discussing it with the rest of the DSG guys Ive decided on white. Al's EVO is white, Bill's 240 Maxi is white, the STi will be

white, as so will mine.

And just so I could get an idea of how it will look, I did a few photochops:

We also discussed a two-tone job, and an all black paint job.

There will be many more pics to come as work continues. All questions, comments, suggestions and concerns are welcome. I am new to the DSM world, but a self proclaimed "Vet" of the Honda nation.

Last edited by a moderator: