Back on all 4, with the fenders just bolted back on with some original factory mounts.

A lot of gussets and a new steering wheel mount.

I added some material to the strut mounts.

I will have 3 injectors per runner. That is a custom 1 1/4" aluminum fuel rail, I just need to weld on some -10 AN fittings. The secondary fuel injectors are as high up the runner as they can be. They are mounted on the bottom to provide a little cleaner look to the engine bay.

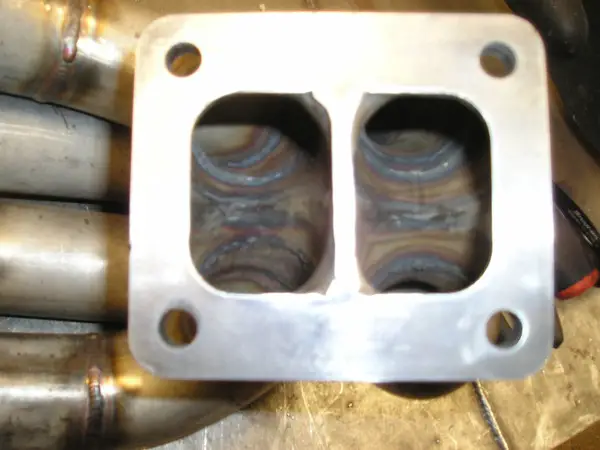

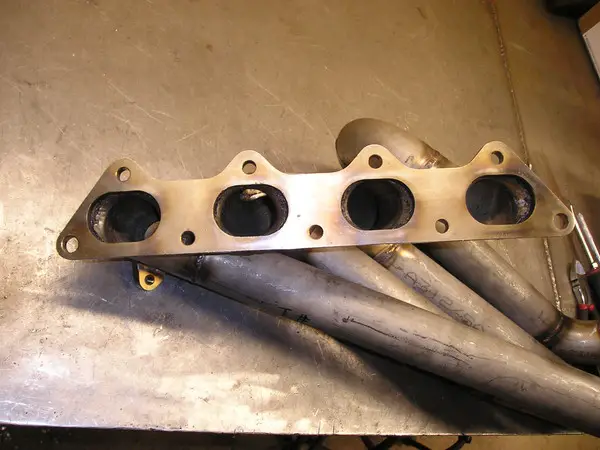

Here is the finished exhaust manifold.

Here is the pipe bender converted to hydraulic power. It now uses a 2" cylinder with a 10" stroke to bend the pipe. This is a 12v DC hydraulic power supply so a car battery with a battery charger back up is used during bending. It will do a 30 deg bend in one stroke of the cylinder and the system is really quiet and works great. We decided to build another work bench along the west wall of the garage so we needed to eliminate the hand operated bending arm. I have a few more pics in my garage section of my photo gallery.

link

~John