TurboTrader

Well-known member

Well, I've had serious cabin fever staying in and taking care of my dear wife after her surgery.

I had a couple free hours today and got out and got a little done to #145. Some of you may have read my other thread about the knock issue I was having.

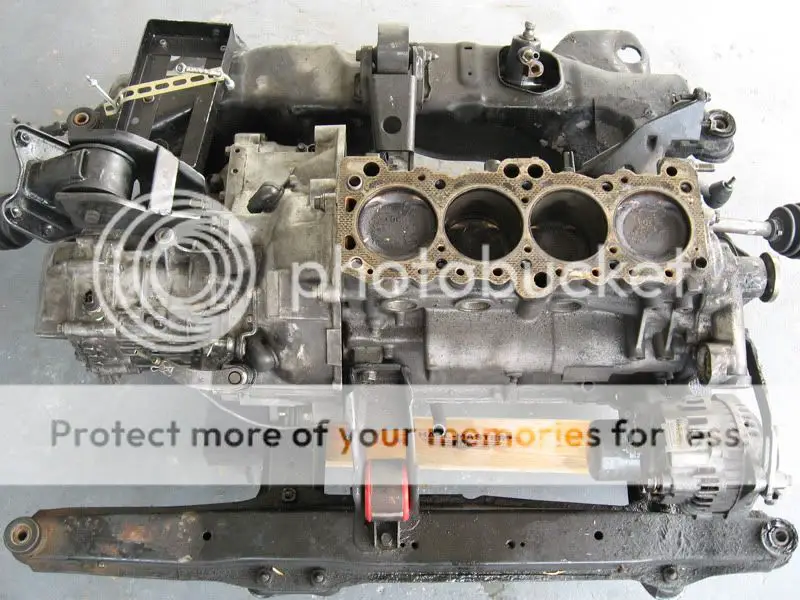

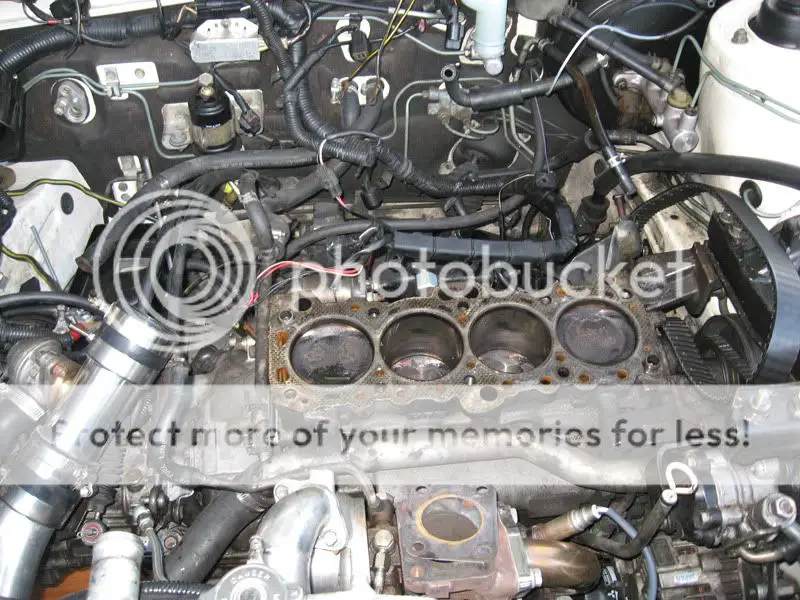

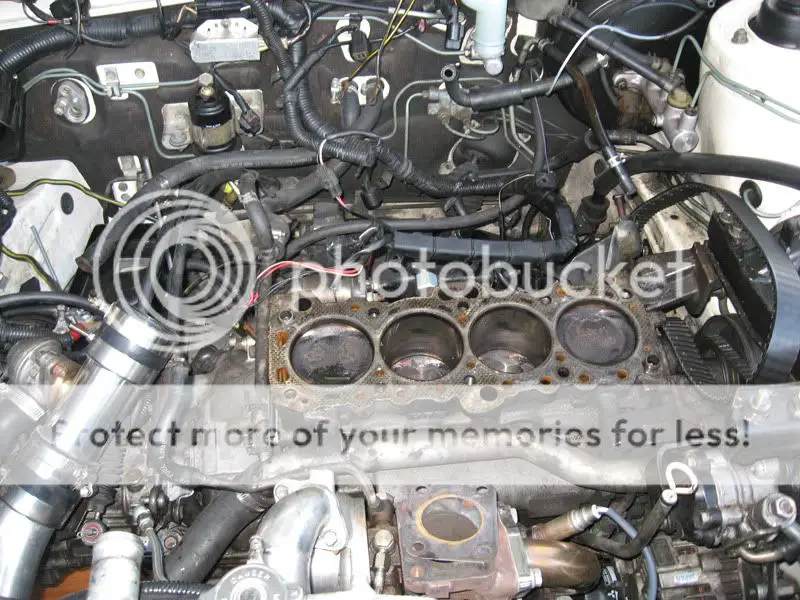

Started out pretty much here this afternoon:

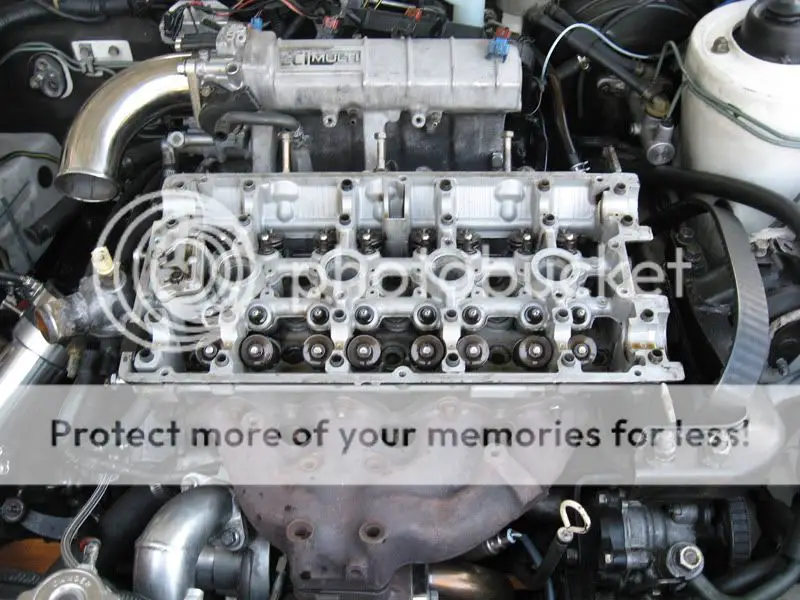

Half-hour later, head looks pretty clean to me:

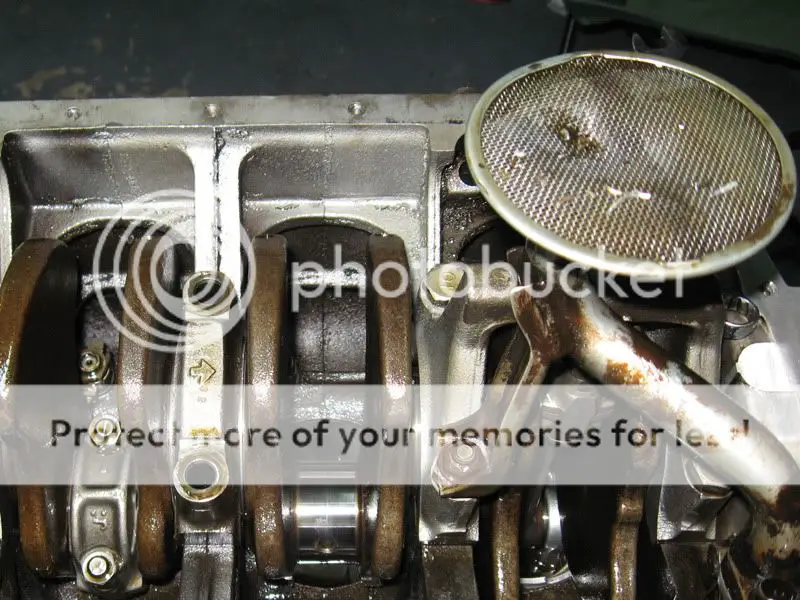

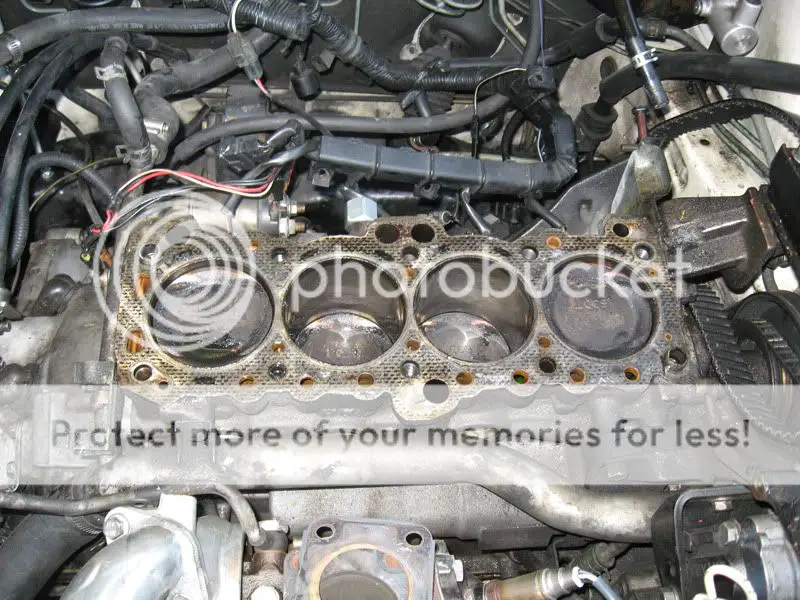

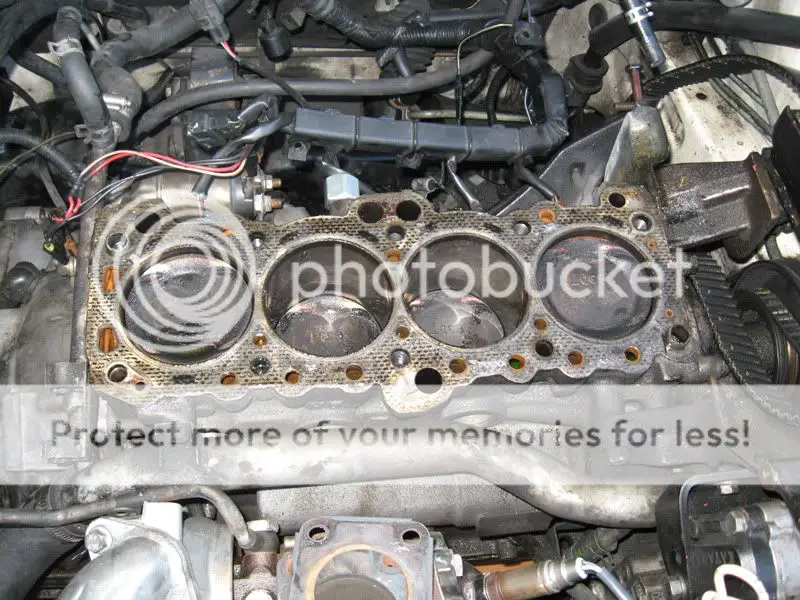

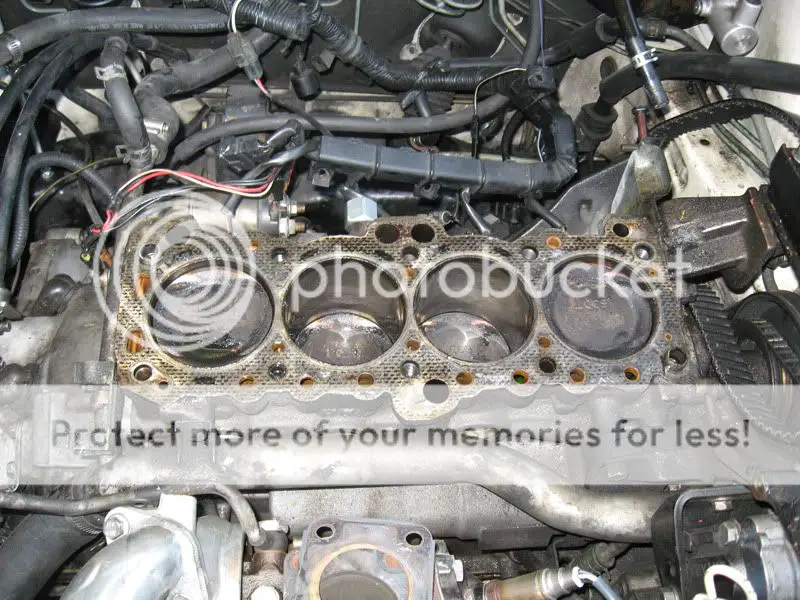

Another half-hour later. Looks pretty nasty to me. I highly doubt this was rebuilt just 12,000 miles ago as I was told. Oh well, I'll get over it and make it much better in the process.

Knock sensor looks to be in the wrong hole as well. When I replaced it twice, I put it in the same hole the original was in, but always thought it felt a bit high up.

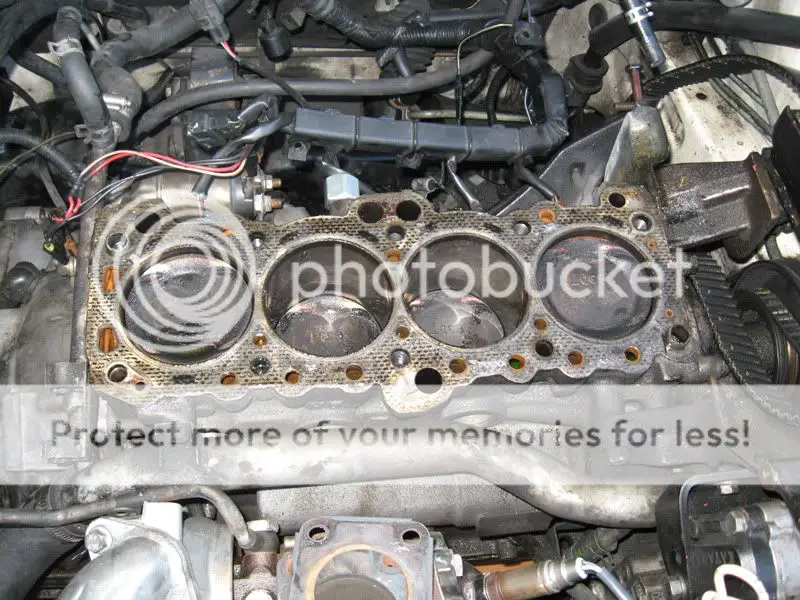

Fel-Pro Composite HG. Held up quite well, actually. Still looks to be fine, although it's going in the garbage.

When the head was rebuilt it appears the stock head bolts were reused! Big no-no!

Some more nastiness. Cylinder walls don't look to terrible, at least no gouges my finger nails can catch, the pistons, however, look absolutely horrid:

Ouch! Non-OEM timing belt, supposedly 12,000 miles old:

Looks like a bit of a lean condition to me. I'll go ahead and attend to the valves while I'm in there:

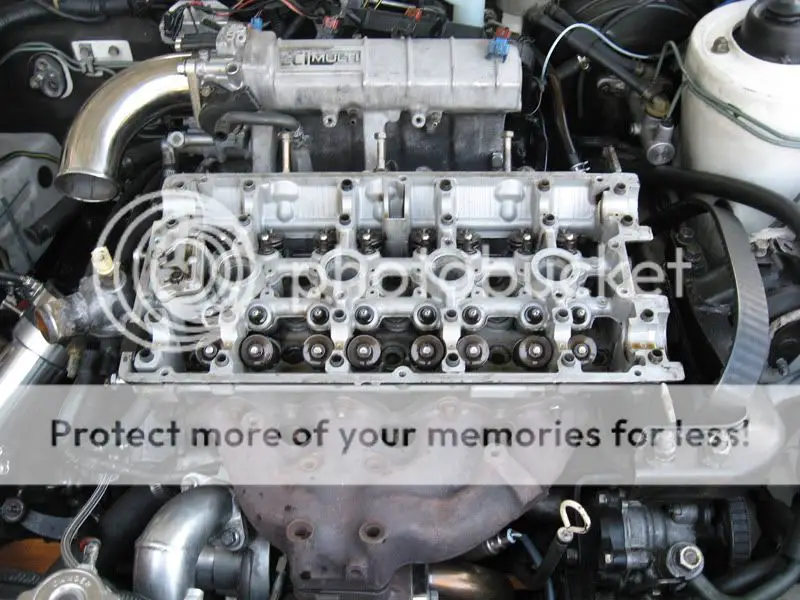

Head completely out. Doesn't look bad at all at the top, still undecided on what to do to it:

That's all for now!

Time to pull the motor out soon and tear into it, but I really don't have the stuff to pull it just yet, so that's about the only set-back for now.

I've also decided I'll be stripping everything from the bay and laying a fresh coat of paint, even though White is so ridiculously hard to keep clean in there. Also a bit of rust where the battery used to be (must have exploded at one time), that I'm still unsure what to do about it.

More progress to come.

I had a couple free hours today and got out and got a little done to #145. Some of you may have read my other thread about the knock issue I was having.

Started out pretty much here this afternoon:

Half-hour later, head looks pretty clean to me:

Another half-hour later. Looks pretty nasty to me. I highly doubt this was rebuilt just 12,000 miles ago as I was told. Oh well, I'll get over it and make it much better in the process.

Knock sensor looks to be in the wrong hole as well. When I replaced it twice, I put it in the same hole the original was in, but always thought it felt a bit high up.

Fel-Pro Composite HG. Held up quite well, actually. Still looks to be fine, although it's going in the garbage.

When the head was rebuilt it appears the stock head bolts were reused! Big no-no!

Some more nastiness. Cylinder walls don't look to terrible, at least no gouges my finger nails can catch, the pistons, however, look absolutely horrid:

Ouch! Non-OEM timing belt, supposedly 12,000 miles old:

Looks like a bit of a lean condition to me. I'll go ahead and attend to the valves while I'm in there:

Head completely out. Doesn't look bad at all at the top, still undecided on what to do to it:

That's all for now!

Time to pull the motor out soon and tear into it, but I really don't have the stuff to pull it just yet, so that's about the only set-back for now.

I've also decided I'll be stripping everything from the bay and laying a fresh coat of paint, even though White is so ridiculously hard to keep clean in there. Also a bit of rust where the battery used to be (must have exploded at one time), that I'm still unsure what to do about it.

More progress to come.