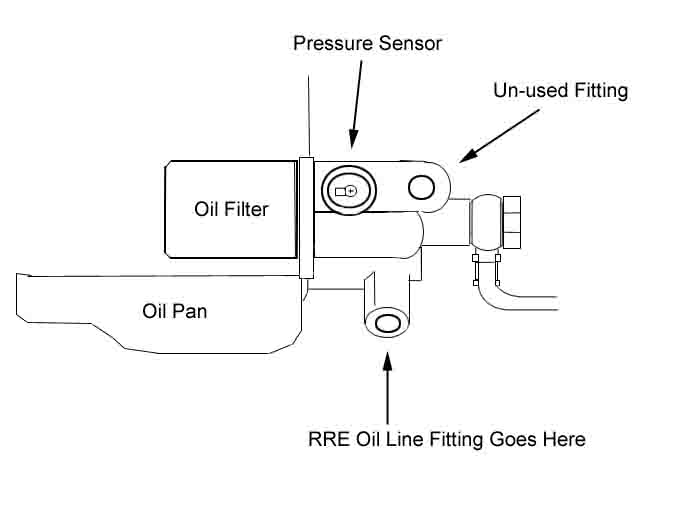

Can an oil feed line from the filter housing give off too much

pressure for a ball bearing turbo?

Was wondering If I should use the factory oil feed location from the

head for a dual ball bearing.

Would you recommend an inline filter, or does the RRE oil feed line already have a filter in the line.. I'll ask around to one of my friends at RRE..

Thanks!

pressure for a ball bearing turbo?

Was wondering If I should use the factory oil feed location from the

head for a dual ball bearing.

Would you recommend an inline filter, or does the RRE oil feed line already have a filter in the line.. I'll ask around to one of my friends at RRE..

Thanks!