Quoting tsitalon1:

Hey Paul, to be 100% honest, I'm not sure what I'm after. Just curious to see what's possible.

I think we are on the same page in that we would like to have as much torque as possible as soon as possible, thus eliminating any lag.

I'm looking for as much power throughout the largest powerband we can get without raising the rpm limit. Ideally I would like 300+ ft/bs from 2.5k-7k.

My application is purely DD street car. Sure it could also be used for other aaplications (autoX) but I would only be using it for DD duties, at least for now.

I have no experience and haven't read at all about the Borg Warner turbo, but I like what you said about it's ability to provide adequate airflow for 450BHP yet spool like a 13b. Not sure how it's doing it...it's not BB or VV right?

In any event, what would happen if we pair the following:

2.6 Stroker @9:1 compression

Borg Warner EFR 7064

Cyclone intake or Kiggly mivec (or both)

93 octane

The more I read about the 2.6 stroker, the more I like it for DD duties. I just don't know how smooth of a motor it would be. As I mentioned before, I hated the vibration caused by the 2.3 Magnus motor I had. I do not want to go through that again!

tsitalon1,

Before we start what's your name? I feel stupid calling you "tsitalon1".

First, it is no crime to not know what you want out of the car. Dyno figures are dyno figures. Two cars can put down similar power figures and be completely different to drive. So some of this is going to boil down to how happy you are with how the car feels rather than what the specs are on paper.

Second, there is nothing wrong with thinking outside the box, sometimes it net results, sometimes it doesn't. No big deal, often these threads reveal a ton of information even if not all of it is directly relevant to the original post. We all learn from it so as long as the discussions remain constructive and respectful we all gain.

Now that said, I don't think there is anything wrong with what you are trying to do but you need to either understand or if you already understand then you need to stop and think about the implications of what you are saying.

"Full boost" is a meaningless term. Up to a point getting full boost at even 2K is actually possibly. Use a small enough snail, enough displacement and the correct cams and you can spool pretty much instantaneously. But you are going to run out of that powerband very, very quickly.

You asked about that 2.6 litre stroker on the EFR 7064. Well like yourself I'm skeptical that a true 450 hp turbo can spool like a 13b but lets just say it produces more power than an E316G and spools faster. Couple that with a high(er) compression 2.6 litre engine, Cyclone and even a MIVEC head and yes I think you'll get lots of low down torque but I don't necessarily think you'll get that long flat torque curve. I think you will spike, put an absolute sh**load of strain on your drivetrain (gearbox, transfer case, axles, clutch etc) right off the bat and then you'll start to tail off in short order.

Now if ultimately at 7,000 rpms or whatever you are still making 300 ft/lbs and you are happy with that (i.e. just getting more in the midrange) then fine, but I personally am not sure that it's going to feel as smooth. Look at the two graphs below.

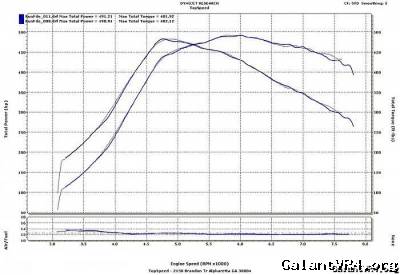

This is a 2.3 litre 4G63 on a GT3076 at 30 psi.

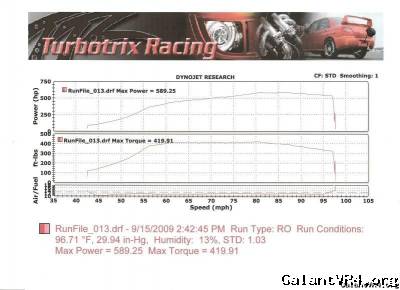

And this is the 2.0 litre long rod at 30 psi on an HTA 3582.

Now before I get criticized for being a "long rod nutswinger", I personally have reservations that the torque curve a long rod motor produces is any better than the one a regular 2.0 litre lump does, they just rev higher (potentially). Then again anything over 8,000 rpms is kind of a moot point on a street motor.

My point is that strokers are often said to be great street motors but I think if you go that route in a desperate attempt to get low down spool you could mess up the dynamics across the rest of the powerband. I also think you run a very strong risk of building something that isn't that nice to drive ... but I could be wrong.