bazeng

Well-known member

Hi Guys,

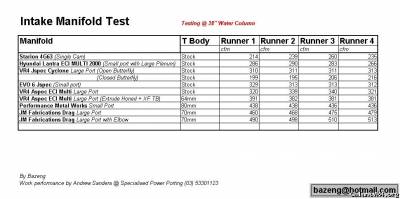

I just thought I'd share some research that I have been doing with a flow bench and various manifolds.

I had the chance to use a friends FLOW BENCH and test some manifolds I had in the garage.

I will add more results as I go on.

Comments appreciated:

________________________________________________________________________________________

Details of test:

JMF Drag Manifold Large Port:

This manifold flowed the highest out of the bunch. The plenum volume was the greatest of them all. We had a few issues with this intake manifold on the flow bench as it had qutie a large amount of turbulence within the plenum chamber. You could hear the helicopter like sound when the flow bench was on full flow.

The effects of this on an engine would probably cause incredible tuning difficulties. Andrew was cluey enough to solve the problem. He quickly used some pipes to change the entry angle which quickly resulted with the loss of turbulance which in turn increased the amount of flow.

I'm not quite sure if JMF is aware of the issue but its a real concern with the performance side of things. Apart from that, quality of welds are excellent, flow was very good and thickness of the sheet alloy is good.

I'm confident to say that I will be using this manifold with the angled entry as it clearly flows very well and is very well made. It may even have something to do with my t/b selection as vehicles already running this manifold haven't had any issues.

JMF on Flow Bench

JMF on Flow Bench

Performance Metal Works (Small Port):

This manifold flowed very well. It had very even distribution and flow a large amount of air. The quality is high, the welds are fantastic. The only downside was that the flange to the head was warped. Also the sheet alloy was on the thin side, but part from that, nothing negative could be said about this manifold.

Magnus Manifold (Large Port):

-to be added--

VR4 Cyclone JSPEC Large Port:

We tested this manifold with the ports closed and open. With the butterflies OPEN, it flowed significantly lower than the ASPEC manifolds. With the option to increase the airspeed by closing the butterflies, the benifit would be bottom end torque so it would be greatly suited to a street car with acceleration in mind.

So for those with aftermarket ECU's, It'll be worth the time and money to get this feature working either with a wastegate actuator of some sort or the use of the stock vac chamber and solenoid.

Ideally you would want the butterflies closed at 0psi or vac, and once boost starts to build, open the ports up. This will also help spool up the turbo sooner.

VR4 ECI Multi ASPEC Large Port:

This manifold is huge for a standard cast item. In comparison, a VL manifold flows about 180cfm per runner. I myself have made over 300kw's at the wheels with this manifold.

VR4 ECI Multi ASPEC Large Port (extrude honed, XF TB):

Flowing almost in the 400cfm range (approx 15% increase over stock), this manifold could be the solution for those that like to drive on the street and also take on the track. Although extrude honing is quite an expensive practice, it keeps the cops at bay and allows you to maintain the stock look. The cost to do this is about $800.00. Used by many rally cars, extrude honing can be done also to exhaust and turbos.

Hyundai ECI 2000 MULTI:

This was tested just because it was sitting in the garage and could possibly be used on an EVO with some port work to match the evo head port shape. Benifits would include larger plenum than EVO1-2-3 plenums and also larger overal port size which could improve top end / mid range.

I'm not sure how much benifit there is to the small evo ports over the large vr4 ports, but I have had an experience with 2 vehicles, both very similar spec, both using similar turbos and cams. The only differences were exhaust manifold, intake manifold (large vs small) and cooler setups. In this case, the VR4 large ports spooled up about 800rpm earlier and made more power throughout the entire rev range.

____________________________________________________________________

Andrew @ specialised power porting / on the flow bench

___________________________________________________________

I just thought I'd share some research that I have been doing with a flow bench and various manifolds.

I had the chance to use a friends FLOW BENCH and test some manifolds I had in the garage.

I will add more results as I go on.

Comments appreciated:

________________________________________________________________________________________

Details of test:

JMF Drag Manifold Large Port:

This manifold flowed the highest out of the bunch. The plenum volume was the greatest of them all. We had a few issues with this intake manifold on the flow bench as it had qutie a large amount of turbulence within the plenum chamber. You could hear the helicopter like sound when the flow bench was on full flow.

The effects of this on an engine would probably cause incredible tuning difficulties. Andrew was cluey enough to solve the problem. He quickly used some pipes to change the entry angle which quickly resulted with the loss of turbulance which in turn increased the amount of flow.

I'm not quite sure if JMF is aware of the issue but its a real concern with the performance side of things. Apart from that, quality of welds are excellent, flow was very good and thickness of the sheet alloy is good.

I'm confident to say that I will be using this manifold with the angled entry as it clearly flows very well and is very well made. It may even have something to do with my t/b selection as vehicles already running this manifold haven't had any issues.

Performance Metal Works (Small Port):

This manifold flowed very well. It had very even distribution and flow a large amount of air. The quality is high, the welds are fantastic. The only downside was that the flange to the head was warped. Also the sheet alloy was on the thin side, but part from that, nothing negative could be said about this manifold.

Magnus Manifold (Large Port):

-to be added--

VR4 Cyclone JSPEC Large Port:

We tested this manifold with the ports closed and open. With the butterflies OPEN, it flowed significantly lower than the ASPEC manifolds. With the option to increase the airspeed by closing the butterflies, the benifit would be bottom end torque so it would be greatly suited to a street car with acceleration in mind.

So for those with aftermarket ECU's, It'll be worth the time and money to get this feature working either with a wastegate actuator of some sort or the use of the stock vac chamber and solenoid.

Ideally you would want the butterflies closed at 0psi or vac, and once boost starts to build, open the ports up. This will also help spool up the turbo sooner.

VR4 ECI Multi ASPEC Large Port:

This manifold is huge for a standard cast item. In comparison, a VL manifold flows about 180cfm per runner. I myself have made over 300kw's at the wheels with this manifold.

VR4 ECI Multi ASPEC Large Port (extrude honed, XF TB):

Flowing almost in the 400cfm range (approx 15% increase over stock), this manifold could be the solution for those that like to drive on the street and also take on the track. Although extrude honing is quite an expensive practice, it keeps the cops at bay and allows you to maintain the stock look. The cost to do this is about $800.00. Used by many rally cars, extrude honing can be done also to exhaust and turbos.

Hyundai ECI 2000 MULTI:

This was tested just because it was sitting in the garage and could possibly be used on an EVO with some port work to match the evo head port shape. Benifits would include larger plenum than EVO1-2-3 plenums and also larger overal port size which could improve top end / mid range.

I'm not sure how much benifit there is to the small evo ports over the large vr4 ports, but I have had an experience with 2 vehicles, both very similar spec, both using similar turbos and cams. The only differences were exhaust manifold, intake manifold (large vs small) and cooler setups. In this case, the VR4 large ports spooled up about 800rpm earlier and made more power throughout the entire rev range.

____________________________________________________________________

Andrew @ specialised power porting / on the flow bench

___________________________________________________________

Last edited: