BogusSVO

Well-known member

This was rather simple to do.... I did not double check the hold downs.. one was not tight enough.......

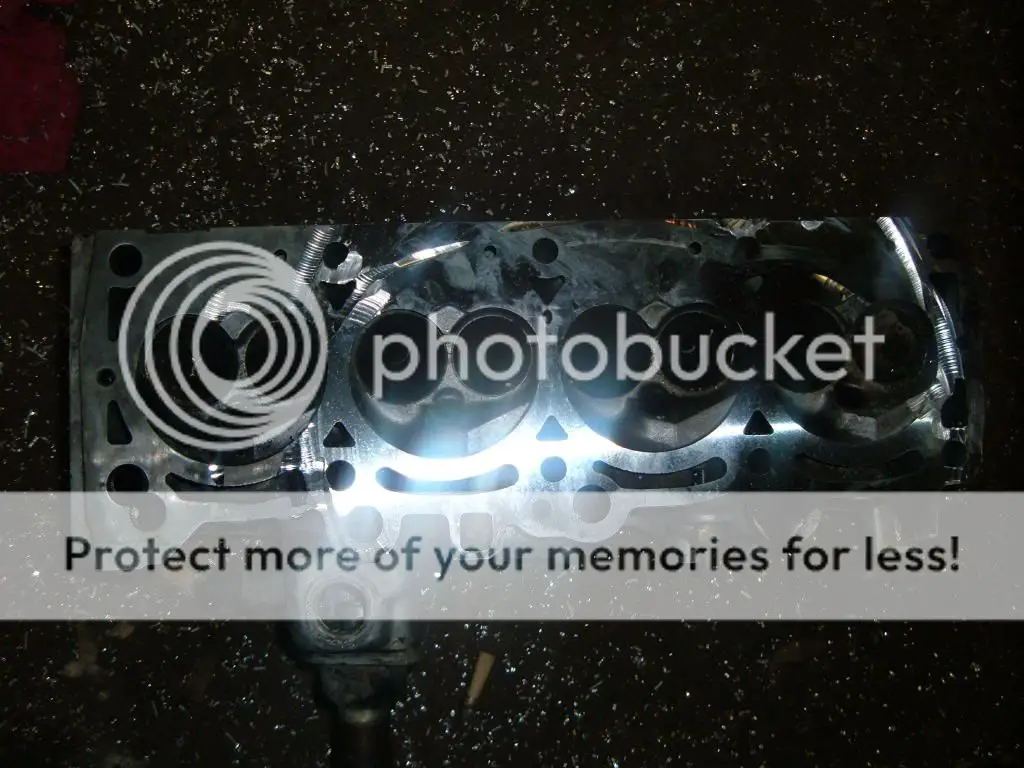

This is /was a Dodge 2.2L/2.5L SOHC

Notice the chunk missing from the side of the head??

When it was thrown out of the machine, it also shattered the cutter blade ($290.00 later) I have another on the way....

This is a good example of why alum heads are so great to work on.... this head that is mangled... can still be saved..... Some welding and some grinding then resurface the head. And a pressure test.. It would work just fine...

Its just not cost feasible to go thu all that work to save this head, when another casting is readily available.

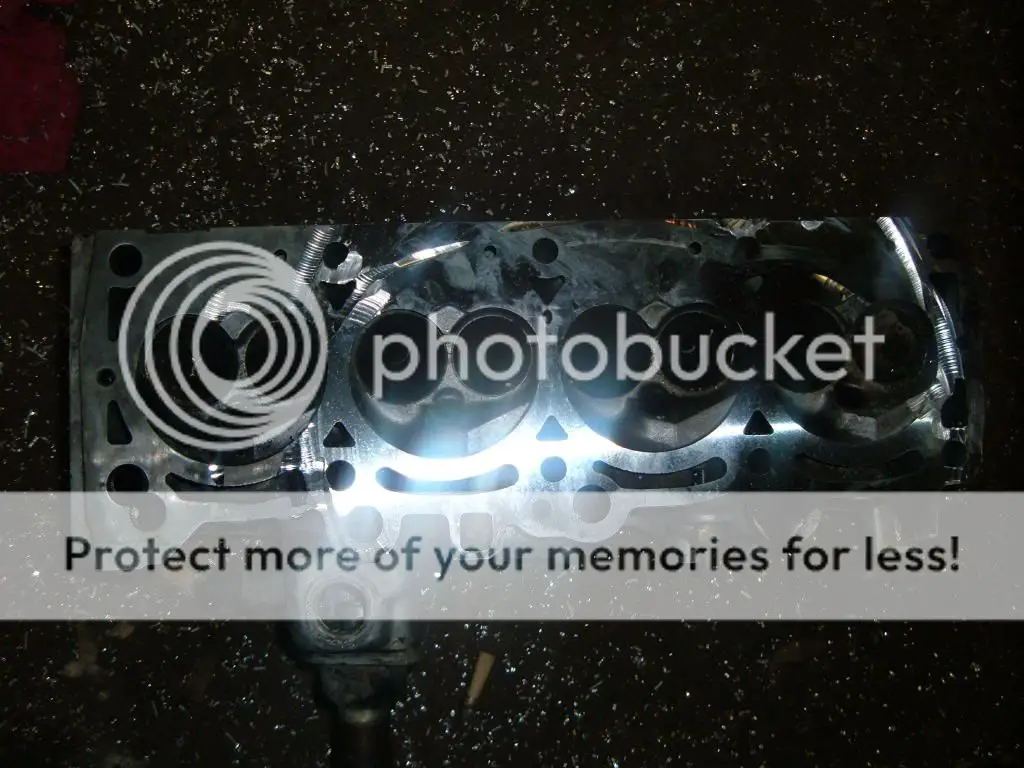

This is /was a Dodge 2.2L/2.5L SOHC

Notice the chunk missing from the side of the head??

When it was thrown out of the machine, it also shattered the cutter blade ($290.00 later) I have another on the way....

This is a good example of why alum heads are so great to work on.... this head that is mangled... can still be saved..... Some welding and some grinding then resurface the head. And a pressure test.. It would work just fine...

Its just not cost feasible to go thu all that work to save this head, when another casting is readily available.