GSTwithPSI

Well-known member

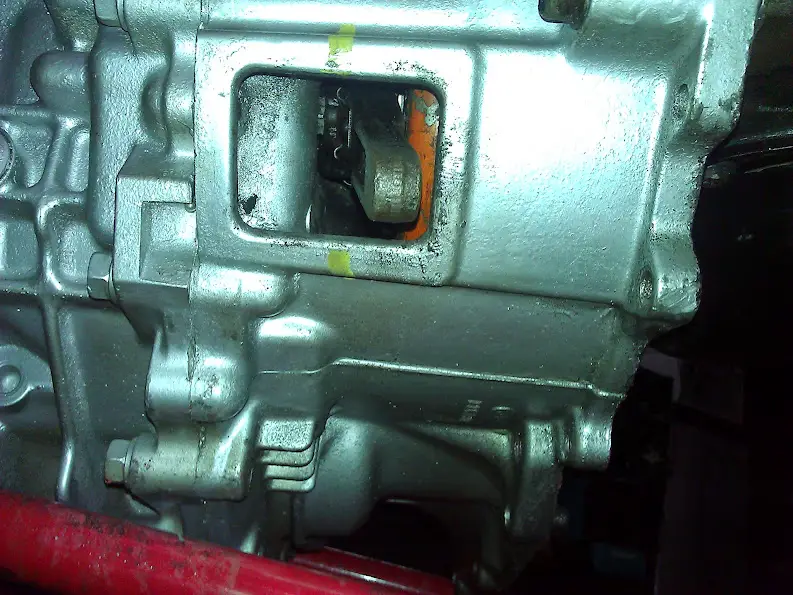

I'm mating my engine and transmission together before dropping the motor in my car. Once the transmission is bolted up to the block, it seems like my clutch fork is sitting a bit too far toward the driver side of the window in the bellhousing. I have just under a 1/4" between the edge of the clutch fork and the edge of the window. There's nothing that I can find that's abnormal about my setup, so I'm thinking the pressure plate fingers just might be taller than average. I'm not super worried, but want someone to sanity check this. Here are all the details:

-Centerforce dual friction organic/carbon composite clutch & pressure plate

-ACT StreetLite Flywheel

-clutch fork in good condition

-New Mitsu OEM TOB

-New pivot ball (not shimmed)

-starter plate is installed

Can someone look at these pictures and throw in their .02?

Just under 1/4" of space in this picture:

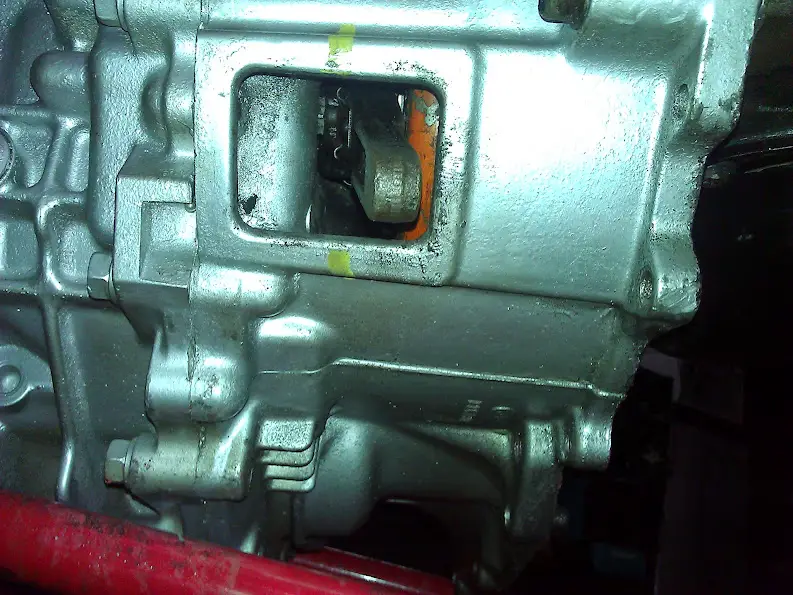

-Centerforce dual friction organic/carbon composite clutch & pressure plate

-ACT StreetLite Flywheel

-clutch fork in good condition

-New Mitsu OEM TOB

-New pivot ball (not shimmed)

-starter plate is installed

Can someone look at these pictures and throw in their .02?

Just under 1/4" of space in this picture: