Kenny_Kline

Well-known member

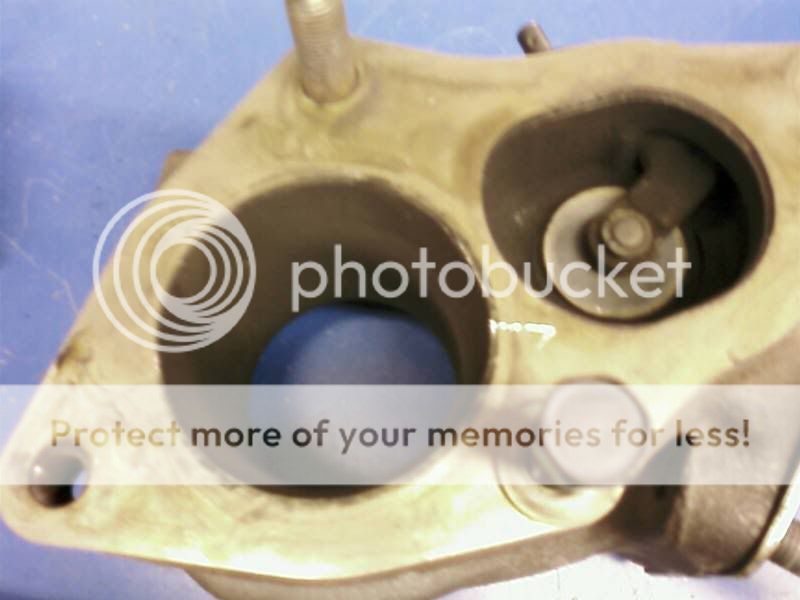

Ok here is the deal. I no longer can run the standard length turbo bolts anymore. The hotside I have has the threads drilled out for some reason. If I wanted to use the standard size length bolts but get thicker bolts, I would have to drill out my manifold bolt holes and then tap the hotside for the larger bolts.

As some of you may know, this is a critical sealing point for the turbo. I cannot have a leak and need to make sure I can torque this flange down good and not have to worry about it leaking.

One option is I was thinking of getting 1/2"-3/4" longer bolts and putting a nut on the other side of the flange. Do it to all 4 and weld the nut in place then take it back apart and there are my threads. Its really the only reasonable thing I can think of but then the question is, what material should the bolt be made out of and what thread pitch. I think a stainless steel bolt will be the best w/ a fine pitch?

Need some reasonable opinions and possibly maybe a better way to seal this gasket . Need a bolt material that can take this kind of stress and heat and wont have issues. Whatever the stock bolts are made out of, thats what I want but needs to be 1/2" longer.

I dont know. Here are a few pics of the flange. I have room for the nut to get under there and if I didnt, I could easily clean up to make one fit.

Also, I am thinking about using ultra grey RTV for the O2 housing to hot side seal. They dont make a gasket big enough for the hotside I have.

As some of you may know, this is a critical sealing point for the turbo. I cannot have a leak and need to make sure I can torque this flange down good and not have to worry about it leaking.

One option is I was thinking of getting 1/2"-3/4" longer bolts and putting a nut on the other side of the flange. Do it to all 4 and weld the nut in place then take it back apart and there are my threads. Its really the only reasonable thing I can think of but then the question is, what material should the bolt be made out of and what thread pitch. I think a stainless steel bolt will be the best w/ a fine pitch?

Need some reasonable opinions and possibly maybe a better way to seal this gasket . Need a bolt material that can take this kind of stress and heat and wont have issues. Whatever the stock bolts are made out of, thats what I want but needs to be 1/2" longer.

I dont know. Here are a few pics of the flange. I have room for the nut to get under there and if I didnt, I could easily clean up to make one fit.

Also, I am thinking about using ultra grey RTV for the O2 housing to hot side seal. They dont make a gasket big enough for the hotside I have.