EfiniX

Well-known member

I know it's different for every car, but I imagine there's a point of diminishing returns chasing more boost at the expense of less timing. Lot's of bits, but the relevant ones here are...

FIC 950cc injectors

Wally 255

T3-T04

264/264 cams

SD setup w/ ECM link

FP racing exhaust w/3" Fujitsubo all the way back

ETS GVR4 FMIC w/ welded pipes

Innovate WB

I've never found 93 octane in Portland, so I run 92. I'm currently pushing 21psi (that's from the OmniBar, not the gauge). I've got knock around 4500 RPM's I'm working out, but I want to make sure I'm going in the right direction. It's just a few counts, but still, you can feel 2 degrees of time getting pulled and it takes all the fun out of it.

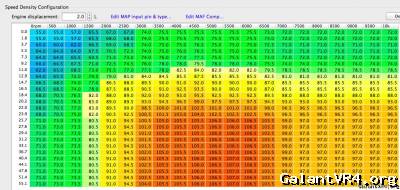

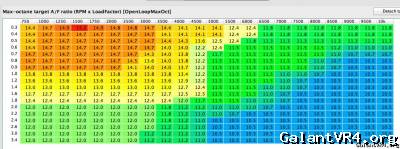

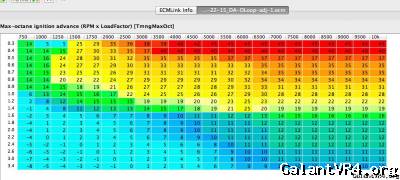

Here's where I'm at in terms of VE, timing, and AFR

Generally, I see my knock right at a 2.4 load-factor between 4500 and 5000 RPM's. I'm also only seeing about 11:1 AFR, so I need to tweak my VE table a bit. That being said, what's (anyone here's) shoot-from-the-hip advice on which direction to go? Lower timing or lower boost? I'm guessing both will sort the knock out, but at this point, I would also wager that one will offer better performance numbers than the other.

FIC 950cc injectors

Wally 255

T3-T04

264/264 cams

SD setup w/ ECM link

FP racing exhaust w/3" Fujitsubo all the way back

ETS GVR4 FMIC w/ welded pipes

Innovate WB

I've never found 93 octane in Portland, so I run 92. I'm currently pushing 21psi (that's from the OmniBar, not the gauge). I've got knock around 4500 RPM's I'm working out, but I want to make sure I'm going in the right direction. It's just a few counts, but still, you can feel 2 degrees of time getting pulled and it takes all the fun out of it.

Here's where I'm at in terms of VE, timing, and AFR

Generally, I see my knock right at a 2.4 load-factor between 4500 and 5000 RPM's. I'm also only seeing about 11:1 AFR, so I need to tweak my VE table a bit. That being said, what's (anyone here's) shoot-from-the-hip advice on which direction to go? Lower timing or lower boost? I'm guessing both will sort the knock out, but at this point, I would also wager that one will offer better performance numbers than the other.