BogusSVO

Well-known member

Pull your balls to properly clean your crank

I know this topic has been talked about some.

Some say it not needed, but I disagree.

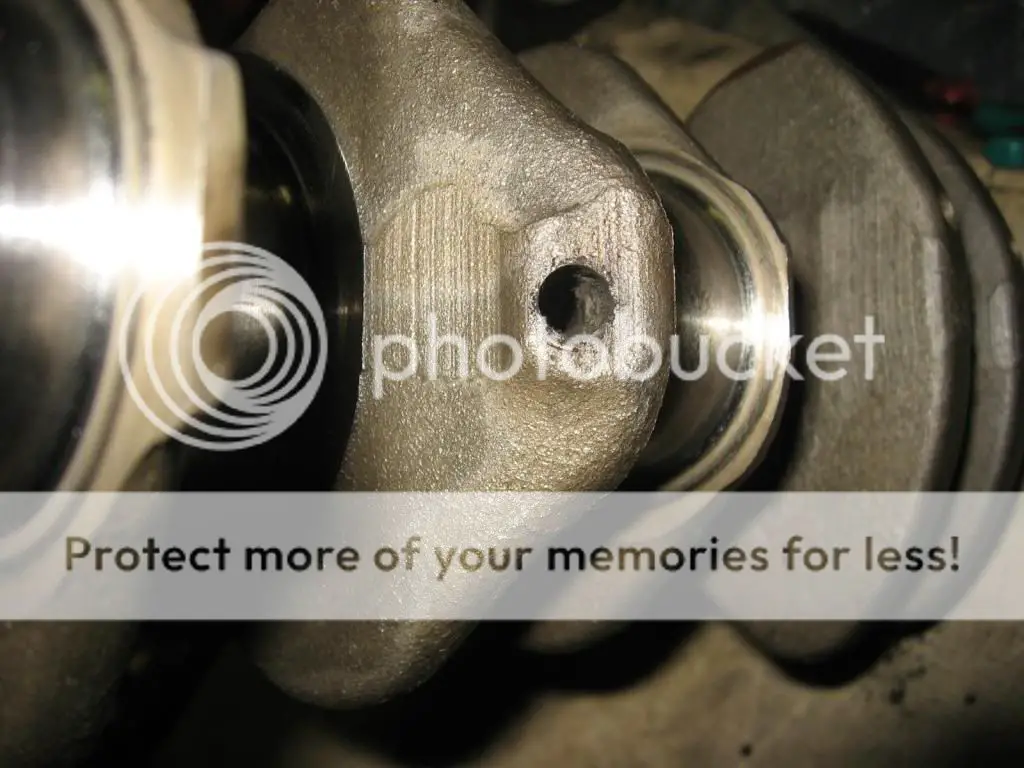

The crank for a 4g63 is of the cross drilled design.

This means that there is an oil galley through both the main and the rod journal with an intersecting oil galley that joins the main to the rod. Due to the way the oil galleys are drilled, from the side of the rod throw to the main journal oil galley, the factory installs a press fit ball.

Now a segment of the intersecting galley is “dead space” this segment is from the cross drilled oil galley in the rod journal to the outside of the rod throw.

The common way to remove the ball is to heat it with a tig welder to loosen it, then weld a pull point on the ball and fight it out.

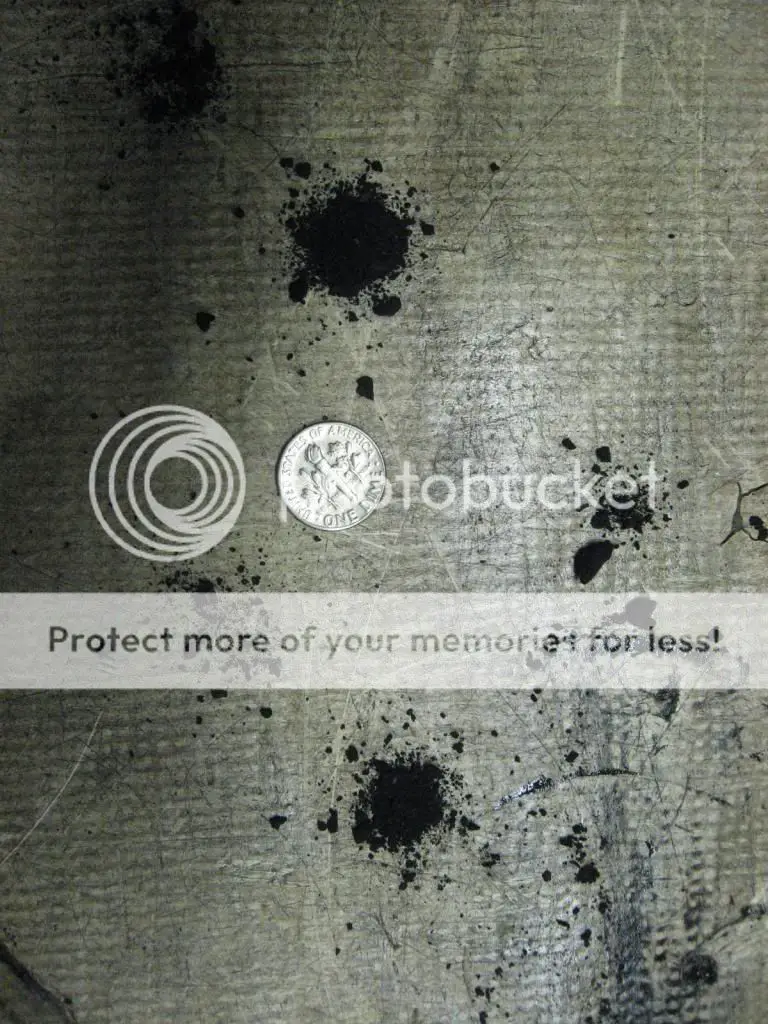

Once the ball is out, you will see the hard packed crud that builds up in the dead space.

Once you have the crud exposed, use a drill bit slightly smaller than the oil galley and drill the crud out, then a small copper brush and compressed air to get the rest out.

You will have 4 piles of crud.

A closer look of the crud from one galley.

So you can have an idea just how much crud is built up in the crank.

I believe that the solvent tanks and spray cabinets that a machine shop uses, also the cans of brake clean the DIY use, breaks down the bond that holds this crud in place and softens it so in a rebuild it gets washed when the engine is primed with oil on the stand, then the new break in oil picks up a small amount of the loosened crud and washes it into the new rod bearings.

I know this topic has been talked about some.

Some say it not needed, but I disagree.

The crank for a 4g63 is of the cross drilled design.

This means that there is an oil galley through both the main and the rod journal with an intersecting oil galley that joins the main to the rod. Due to the way the oil galleys are drilled, from the side of the rod throw to the main journal oil galley, the factory installs a press fit ball.

Now a segment of the intersecting galley is “dead space” this segment is from the cross drilled oil galley in the rod journal to the outside of the rod throw.

The common way to remove the ball is to heat it with a tig welder to loosen it, then weld a pull point on the ball and fight it out.

Once the ball is out, you will see the hard packed crud that builds up in the dead space.

Once you have the crud exposed, use a drill bit slightly smaller than the oil galley and drill the crud out, then a small copper brush and compressed air to get the rest out.

You will have 4 piles of crud.

A closer look of the crud from one galley.

So you can have an idea just how much crud is built up in the crank.

I believe that the solvent tanks and spray cabinets that a machine shop uses, also the cans of brake clean the DIY use, breaks down the bond that holds this crud in place and softens it so in a rebuild it gets washed when the engine is primed with oil on the stand, then the new break in oil picks up a small amount of the loosened crud and washes it into the new rod bearings.