BogusSVO

Well-known member

4G63T Block Correction

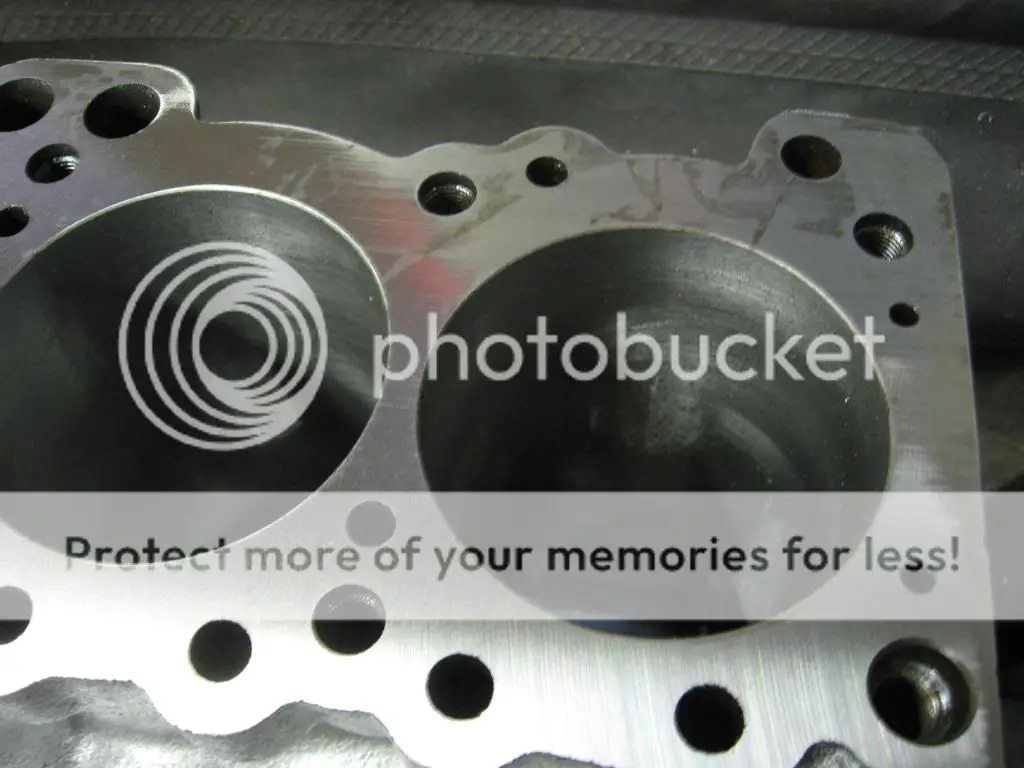

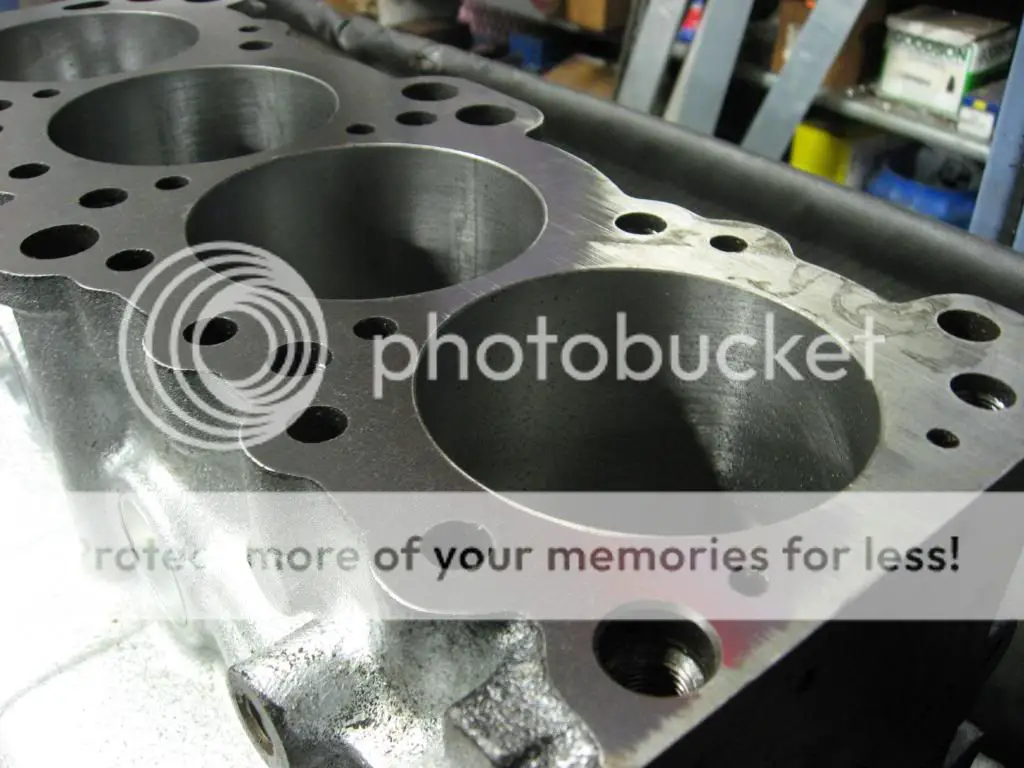

This block was machined at another shop, then ended up at my shop.

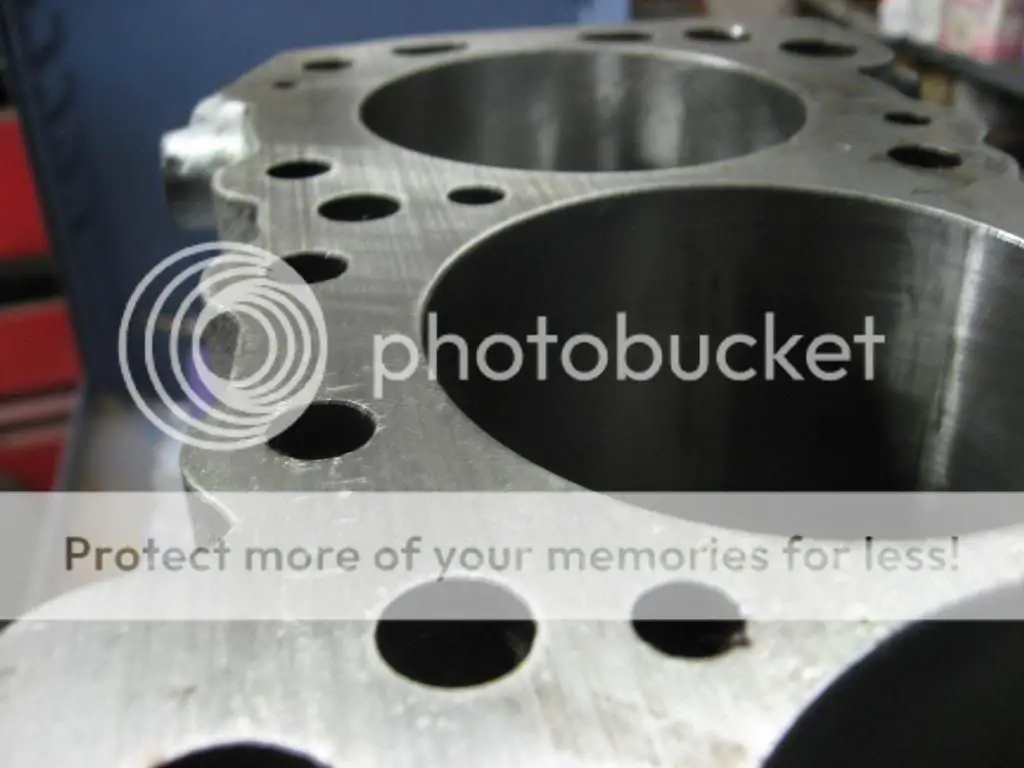

To start with the block gasket surface was belt surfaced.

I have heard of this being done, but this was the first time I have seen it in person.

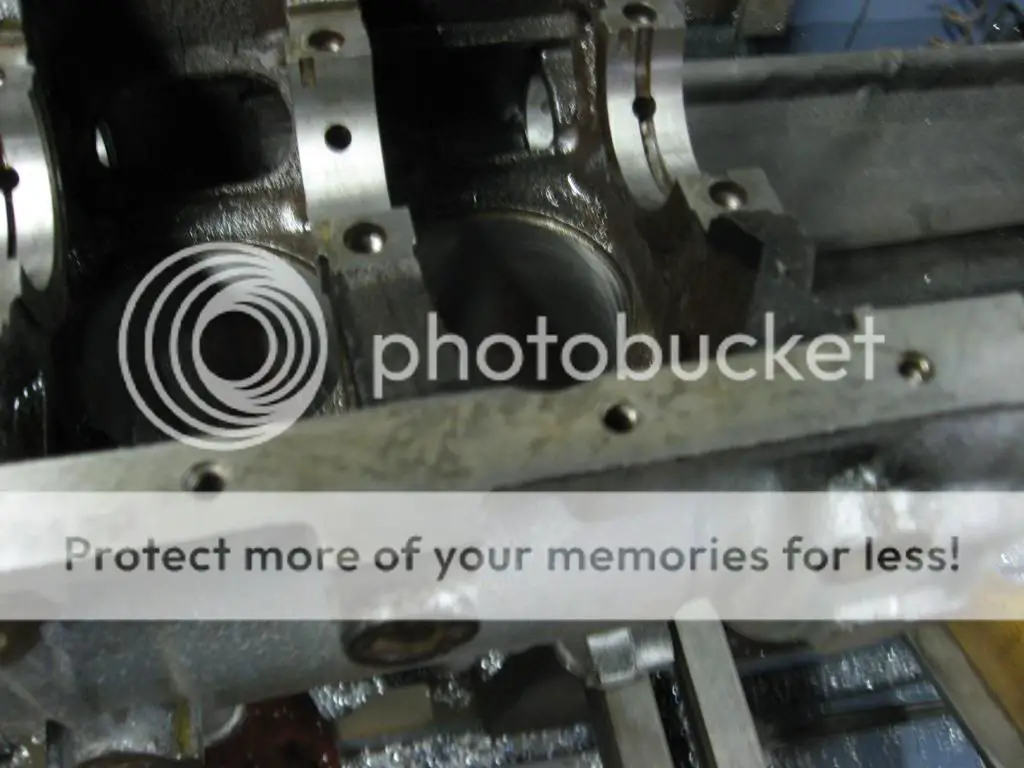

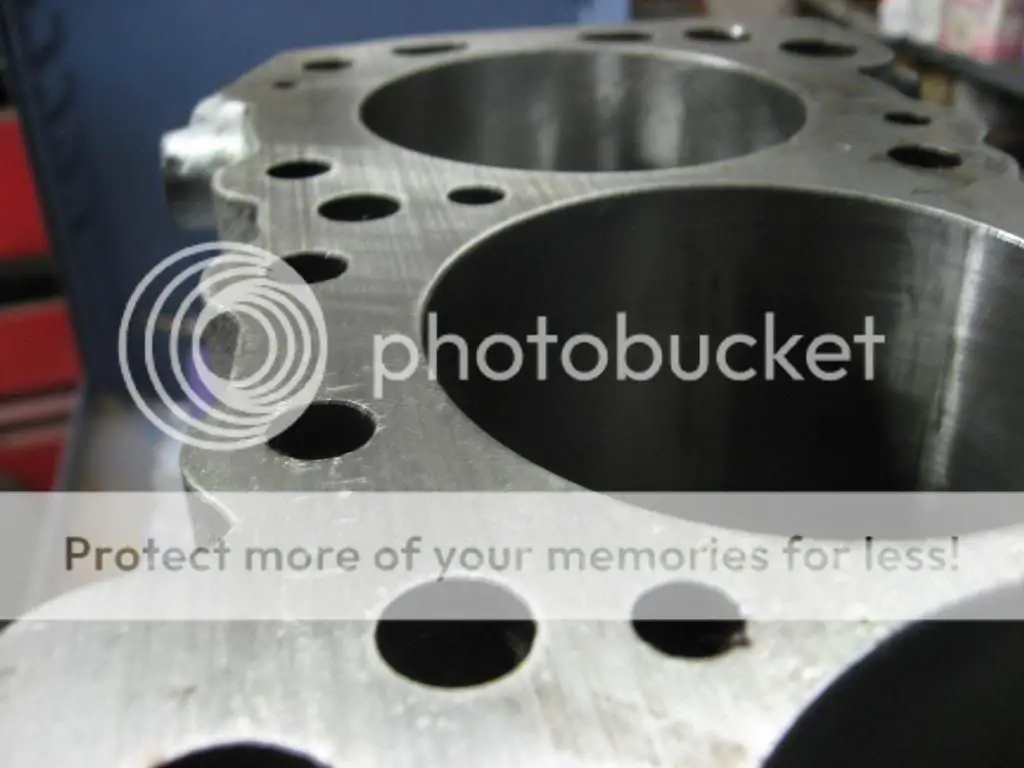

A longer view

The hone job was sub par also. But I did not get a pic of that.

When setting the block up to be milled, I did the “quick set up”

This method indexes the gasket surface to the oil pain rails, and not the main journals.

The oil pan rails had some light surface rust on them

I long boarded the oil pain rails, to make sure they were clean and no burs that would hinder the accuracy of the set up.

After they were cleaned.

I do not much care for this set up, for the simple reason that most block oil rails have a wide range in tolerance.

Some shops will set up like this and then use shims to level the block deck.

I found .002 tilt from front to back on this set up. That dose not seem too bad.

But Blocks are NOT machined to the oil pan rails, they are machined indexed to the main journals.

So I took this set up down and set up to deck the block to the mains.

This is the bar the main journals of the block will rest on.

I checked the bar and it had less than .0005 from end to end distortion.

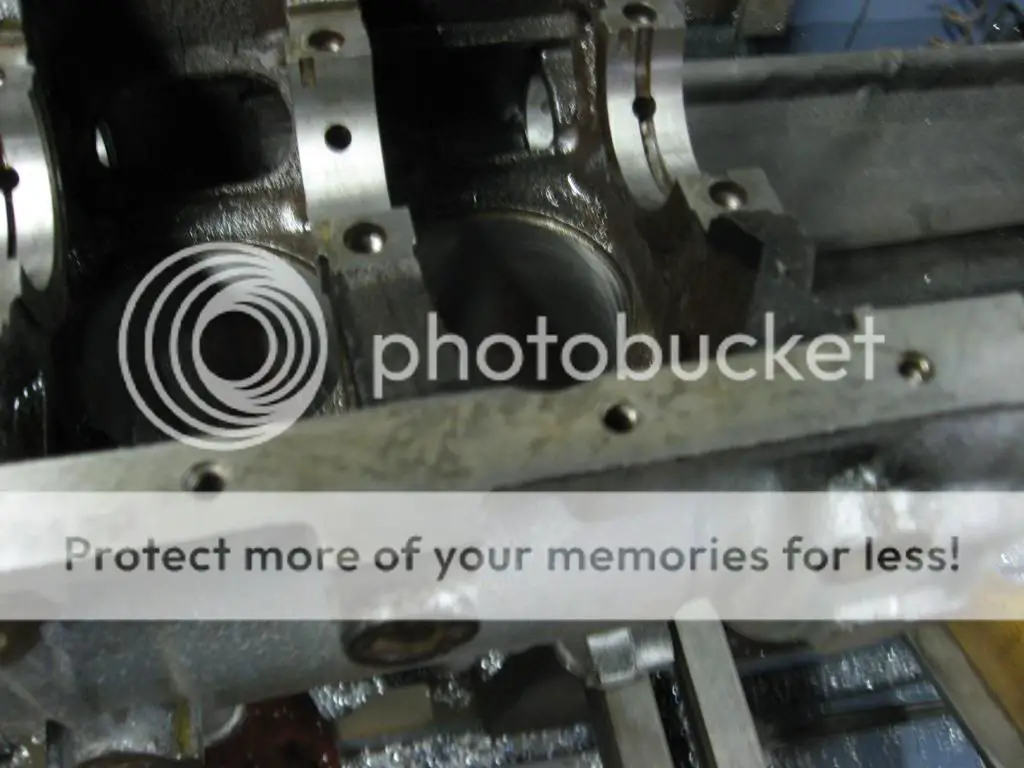

Setting the block on the bar

Notice the hold down on the left side.

Now that the block is set up on the mains, checking the tilt showed .0045

This lets me know the oil pain rails are .002 off from the main journals.

Now to mill the block, I will start with a .0005 “getting to know you pass”

Now that I am sure of the set up, I cut another .002

The block still has a low corner.

After another .002 pass for a total of .0045 removed, I was left with this.

I made a final pass of .001 for a total mill of .0055 removed.

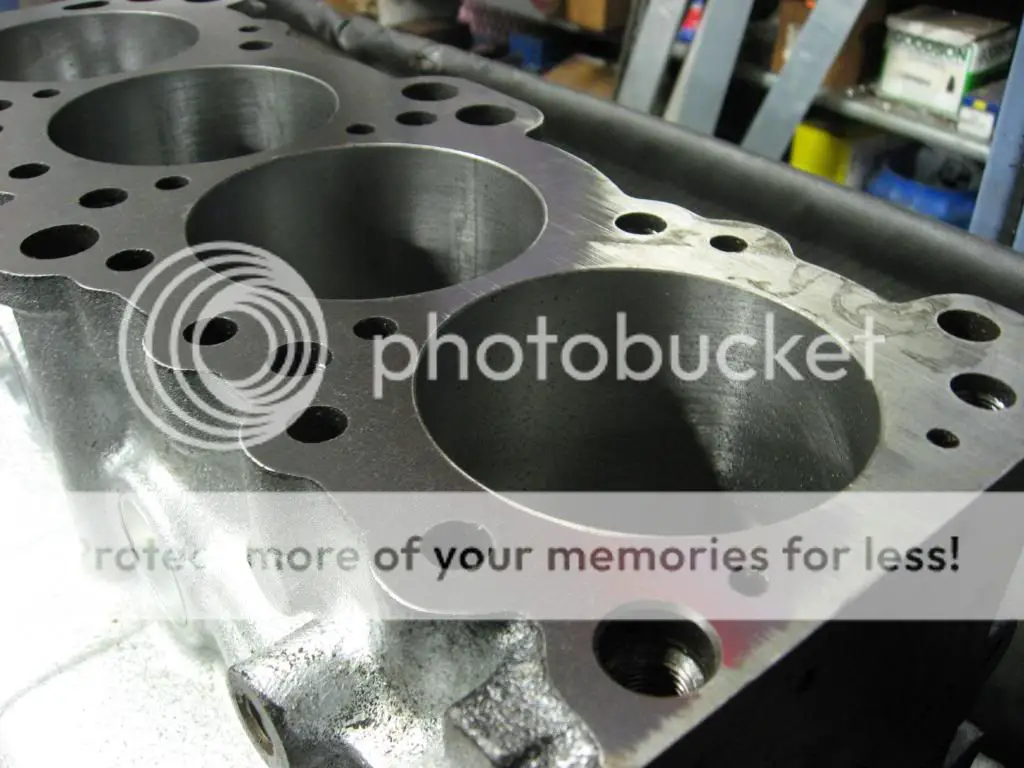

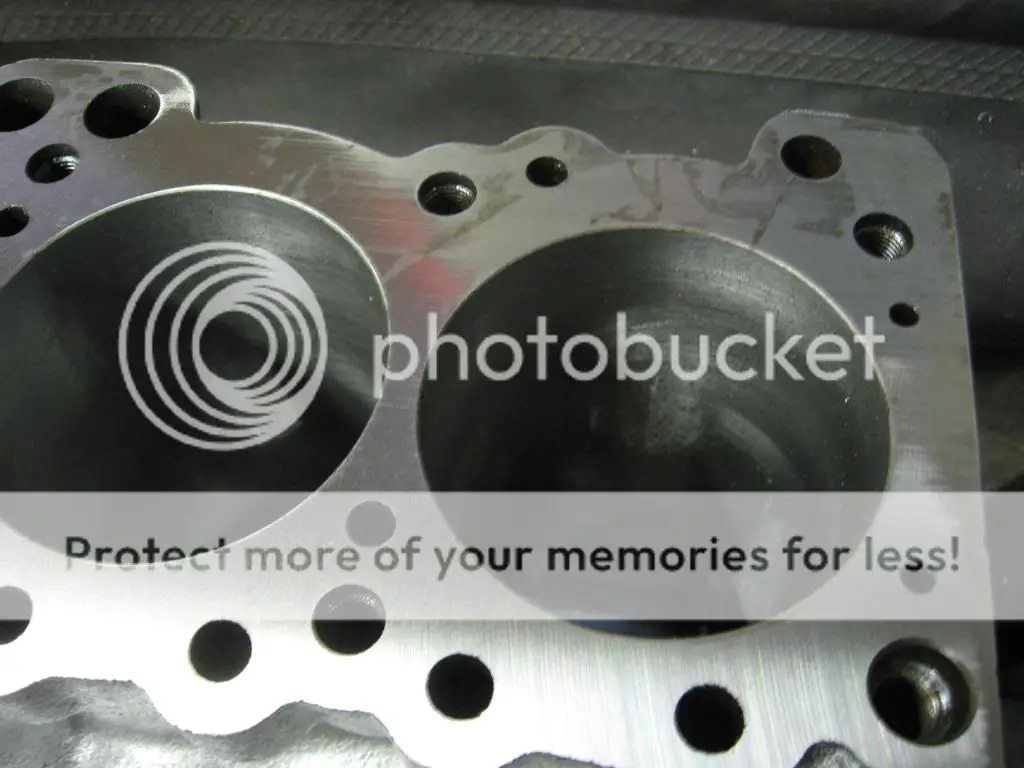

Now that the block was milled, it removed some of the top champher from the cylinder bore, this aids in the installation of the piston and rings into the block.

The “hi-tech” tool used to champher the block.

The cylinder on the left has had the champher cut, the right has not been.

The crosshatch I honed in the block.

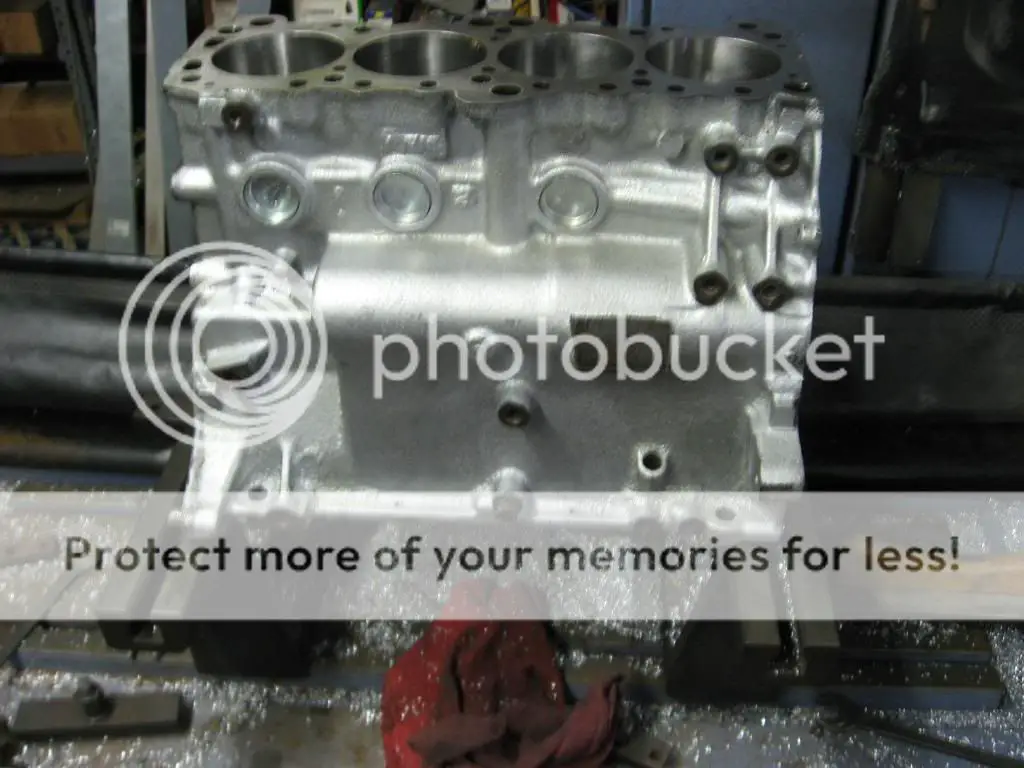

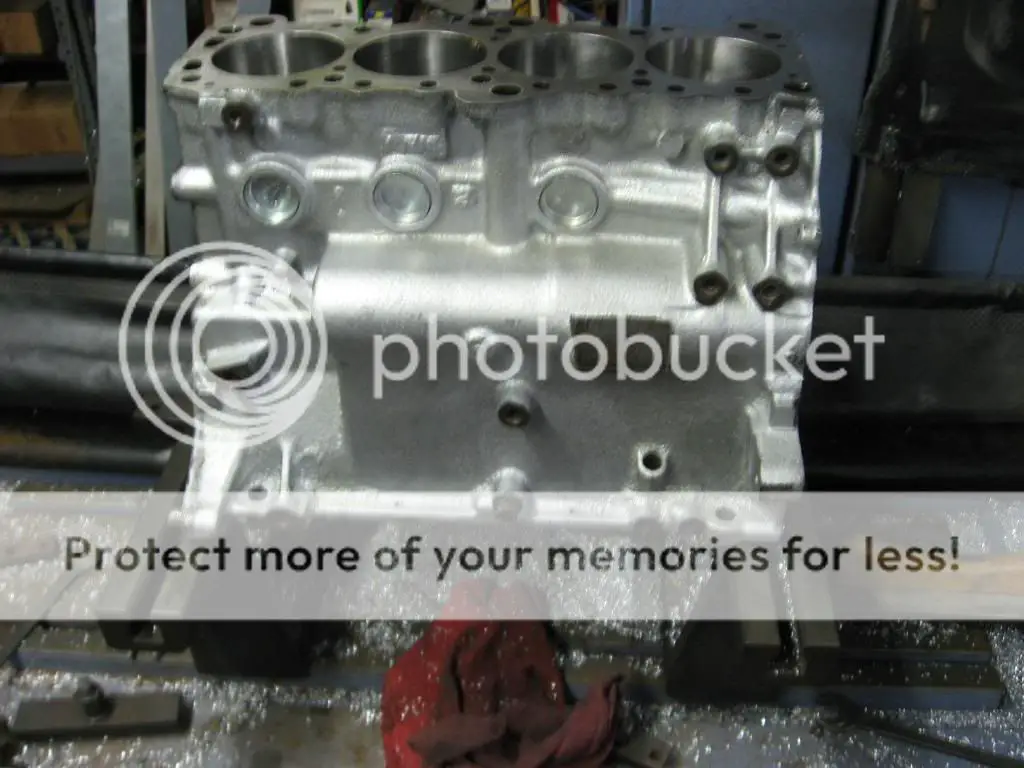

After the block has been washed to remove metal flake and grit from machining.

This block still will need a final wash before assembly.

This block was machined at another shop, then ended up at my shop.

To start with the block gasket surface was belt surfaced.

I have heard of this being done, but this was the first time I have seen it in person.

A longer view

The hone job was sub par also. But I did not get a pic of that.

When setting the block up to be milled, I did the “quick set up”

This method indexes the gasket surface to the oil pain rails, and not the main journals.

The oil pan rails had some light surface rust on them

I long boarded the oil pain rails, to make sure they were clean and no burs that would hinder the accuracy of the set up.

After they were cleaned.

I do not much care for this set up, for the simple reason that most block oil rails have a wide range in tolerance.

Some shops will set up like this and then use shims to level the block deck.

I found .002 tilt from front to back on this set up. That dose not seem too bad.

But Blocks are NOT machined to the oil pan rails, they are machined indexed to the main journals.

So I took this set up down and set up to deck the block to the mains.

This is the bar the main journals of the block will rest on.

I checked the bar and it had less than .0005 from end to end distortion.

Setting the block on the bar

Notice the hold down on the left side.

Now that the block is set up on the mains, checking the tilt showed .0045

This lets me know the oil pain rails are .002 off from the main journals.

Now to mill the block, I will start with a .0005 “getting to know you pass”

Now that I am sure of the set up, I cut another .002

The block still has a low corner.

After another .002 pass for a total of .0045 removed, I was left with this.

I made a final pass of .001 for a total mill of .0055 removed.

Now that the block was milled, it removed some of the top champher from the cylinder bore, this aids in the installation of the piston and rings into the block.

The “hi-tech” tool used to champher the block.

The cylinder on the left has had the champher cut, the right has not been.

The crosshatch I honed in the block.

After the block has been washed to remove metal flake and grit from machining.

This block still will need a final wash before assembly.