turbowop

Well-known member

Because I'm installing ECMlink, I have to rewire my methanol injection setup. Reason being, the trigger wire on the old Maftpro setup was a 12v input to switch to secondary fuel/timing maps and ECMlink requires a switched ground input on the idle switch input to switch to secondary fuel/timing maps.

I could just use a second relay to switch polarity on one 12v output wire, but I don't want to introduce more failure points into the system. I'd like to keep with one relay so that if it goes bad, the whole system shuts down.

I need to get the car up and running this weekend so that I can drive it around and get a base tune going so that I can drive 2.5hrs to English Racing and have Aaron and Lucas tune the car on their dyno. I've already got the car started, but I can't drive it until I finish this wiring and get the carpet and seats back in. I wanna get it right the first time, yanno?

Please excuse my hand-drawn diagrams. /ubbthreads/images/graemlins/rofl.gif

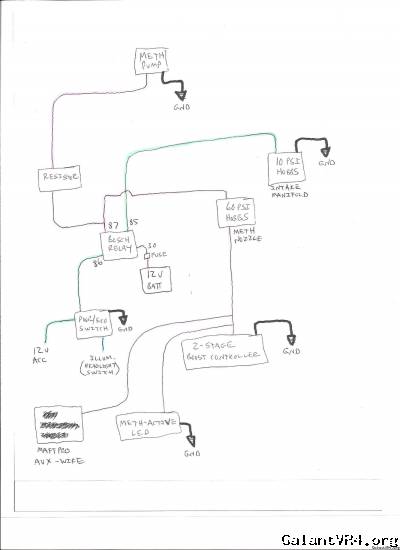

This is a pieced together English Racing meth kit. If you're wondering, the resistor is so that the pump doesn't see full 12v. I guess it's not good for the pump to see that much voltage over time and it's not required anyway, as per Lucas' directions. Or it was too much pressure output. I can't remember. Whatever it was, using the resistor was his tried and true method to this setup so there it is. The 10psi Hobbs switch completes the Pwr/Eco switch circuit, allowing power to flow through the relay to power the meth pump and also sends 12v to the 60psi Hobbs switch. Once that switch sees 60psi meth pressure, it allows 12v to flow the two-stage boost controller to raise boost, as well as to the Maftpro to switch to the secondary fuel/timing map and sends power to the LED to let me know meth is spraying. If that 60psi Hobbs doesn't see meth pressure due to a clog or empty tank, everything reverts back to lower boost and regular fuel/timing maps, hopefully saving me from ending up with a hole in the engine block.

Old setup:

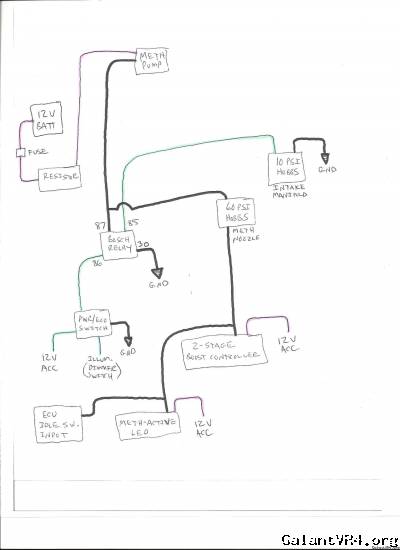

New setup (I think):

Did I correctly draw the new diagram? Thanks!

I could just use a second relay to switch polarity on one 12v output wire, but I don't want to introduce more failure points into the system. I'd like to keep with one relay so that if it goes bad, the whole system shuts down.

I need to get the car up and running this weekend so that I can drive it around and get a base tune going so that I can drive 2.5hrs to English Racing and have Aaron and Lucas tune the car on their dyno. I've already got the car started, but I can't drive it until I finish this wiring and get the carpet and seats back in. I wanna get it right the first time, yanno?

Please excuse my hand-drawn diagrams. /ubbthreads/images/graemlins/rofl.gif

This is a pieced together English Racing meth kit. If you're wondering, the resistor is so that the pump doesn't see full 12v. I guess it's not good for the pump to see that much voltage over time and it's not required anyway, as per Lucas' directions. Or it was too much pressure output. I can't remember. Whatever it was, using the resistor was his tried and true method to this setup so there it is. The 10psi Hobbs switch completes the Pwr/Eco switch circuit, allowing power to flow through the relay to power the meth pump and also sends 12v to the 60psi Hobbs switch. Once that switch sees 60psi meth pressure, it allows 12v to flow the two-stage boost controller to raise boost, as well as to the Maftpro to switch to the secondary fuel/timing map and sends power to the LED to let me know meth is spraying. If that 60psi Hobbs doesn't see meth pressure due to a clog or empty tank, everything reverts back to lower boost and regular fuel/timing maps, hopefully saving me from ending up with a hole in the engine block.

Old setup:

New setup (I think):

Did I correctly draw the new diagram? Thanks!

Last edited: