citymunky

Well-known member

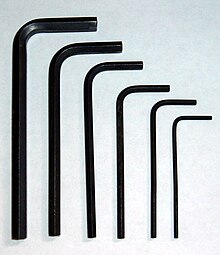

I'm looking to replace my Downpipe hex bolts with something easily like allen head bolts. The reason being the 3" downpipe is a PITA to install. It's maybe 1/4" after the flange the pipe turns into 3 inches, making it a pain to install. I can't use a socket because it doesn't fit, meaning I need to tighten those bolts with a wrench or crowsfoot 1/8" turn at a time.

Spec's M12x1.25 40mm

I tried Fastnal, Ace Hardware, Home Deport, Lowes, and none are to be found locally. I found some online M12x1.25x50 here https://www.belmetric.com/bsh12x125x50-allen-head-p-2087.html?cPath=6_339_362_365. Should I worry about seizing? Has anybody done this before?

Spec's M12x1.25 40mm

I tried Fastnal, Ace Hardware, Home Deport, Lowes, and none are to be found locally. I found some online M12x1.25x50 here https://www.belmetric.com/bsh12x125x50-allen-head-p-2087.html?cPath=6_339_362_365. Should I worry about seizing? Has anybody done this before?