BogusSVO

Well-known member

How to R&R pistons and Balance Rods

1G 6 Bolt 4G63T

The used rods and pistons, the pistons are being replaced due to cracked and broken ring lands.

I start off by marking the front of the rod with a center punch

Next is to find the proper sized press pieces to press out the wrist pins.

Due to the pressures used to press out the wrist pin, care must be used, the piston itself can bust sending pieces of it flying that can and will cause injury.

After the pistons have been pressed off, and the small end inspected for scoring, the rods need to be numbered on both the rod and end cap.

Now the rod and caps can be split and cleaned, I use a glass beader to remove all the grime

Once that is done I spray them down with a good brake cleaner and blow them dry

Chase the rod bolt threads with a nut to remove any dust left from the glass beading.

Now to match the rods back with the caps

Install the rod nuts.

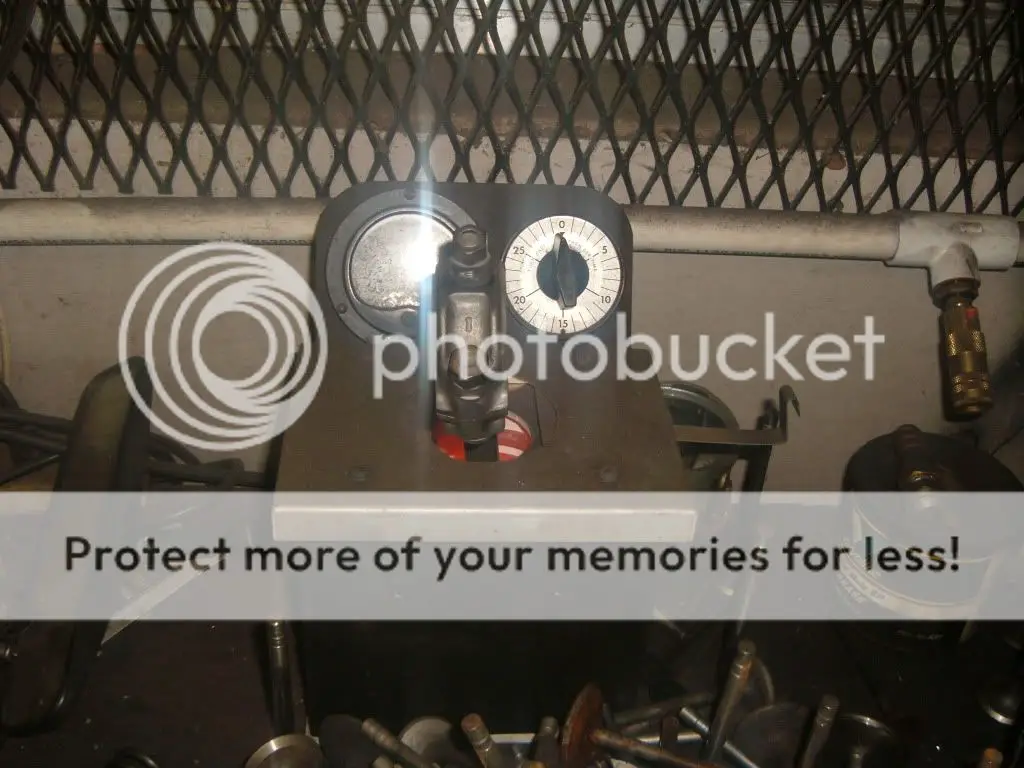

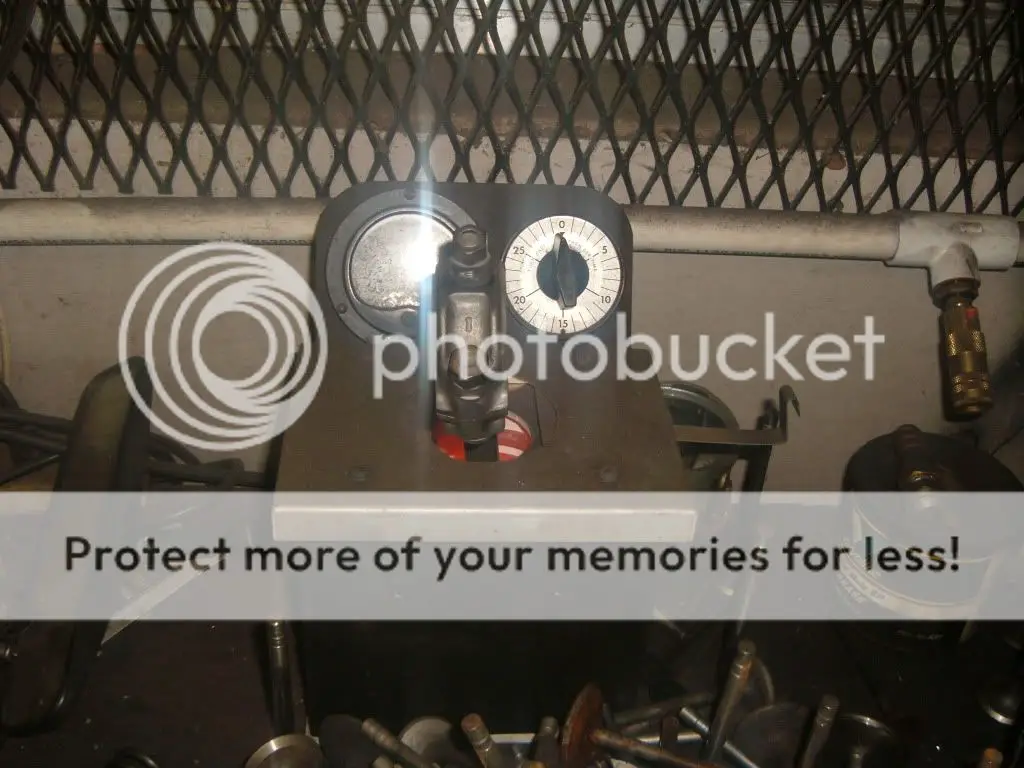

Now the rods are clean and assembled, they can be balanced. Start off by weighing all the small ends

The weight will be matched to the lightest one.

Once the small ends are matched, weigh the overall weight of each rod, and match the overall weight by removing material from the bottom of the rod.

Now that is done, it is time to match the weights of the pistons WITH OUT the wrist pin installed.

Then weight match the wrist pins.

Now that all the weights are with in 1/10 a gram the pistons can be hung back on the connecting rods. The small ends must be heated so the wrist pin can slip through it.

This must be done very quickly so the wrist pin is fully in place before the small end of the rod contracts around the wrist pin holding it in place.

1G 6 Bolt 4G63T

The used rods and pistons, the pistons are being replaced due to cracked and broken ring lands.

I start off by marking the front of the rod with a center punch

Next is to find the proper sized press pieces to press out the wrist pins.

Due to the pressures used to press out the wrist pin, care must be used, the piston itself can bust sending pieces of it flying that can and will cause injury.

After the pistons have been pressed off, and the small end inspected for scoring, the rods need to be numbered on both the rod and end cap.

Now the rod and caps can be split and cleaned, I use a glass beader to remove all the grime

Once that is done I spray them down with a good brake cleaner and blow them dry

Chase the rod bolt threads with a nut to remove any dust left from the glass beading.

Now to match the rods back with the caps

Install the rod nuts.

Now the rods are clean and assembled, they can be balanced. Start off by weighing all the small ends

The weight will be matched to the lightest one.

Once the small ends are matched, weigh the overall weight of each rod, and match the overall weight by removing material from the bottom of the rod.

Now that is done, it is time to match the weights of the pistons WITH OUT the wrist pin installed.

Then weight match the wrist pins.

Now that all the weights are with in 1/10 a gram the pistons can be hung back on the connecting rods. The small ends must be heated so the wrist pin can slip through it.

This must be done very quickly so the wrist pin is fully in place before the small end of the rod contracts around the wrist pin holding it in place.