- Software Upgraded - Reset Your Password to Login

In order to log in after the forum software change, you need to reset your password. If you don't have access to the email address you used to register your GVR4.org account, you won't be able to reset your password. In that case, follow the instructions here to regain access to the forum.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8.8 in a GVR4

- Thread starterTerrance362

- Start date

Boostin21

Well-known member

yea the APC EVO II is the way to go. the yellow car from Rob Barac.

utilizes a supra MA70 rear diff with a different ratio and custom axles.

thats what i am going to be using for my current project.

utilizes a supra MA70 rear diff with a different ratio and custom axles.

thats what i am going to be using for my current project.

fivestardsm

Well-known member

Terrance362

Well-known member

Sup everybody. I have a question for. Please if you dont have a answer please no stupid replys.

Well I have the rear end out and I have made the blue-print of the frame that I am going to use. I am going to use Square tubing. But the thickness is what I am thinking about. I want to go buy a welder to put it together. Harbor freight was what I was thinking. Do you guys think that welder would hold it. The only reason why I was looking at that one was because I dont have a 220 in my storage building or gas. The frame is going to mount in the factory location of the rear end. I am going to use a pan hard. Still not to clear about the four link, or gearing. Please input. Not stupid sh*t please /ubbthreads/images/graemlins/cool.gif

Well I have the rear end out and I have made the blue-print of the frame that I am going to use. I am going to use Square tubing. But the thickness is what I am thinking about. I want to go buy a welder to put it together. Harbor freight was what I was thinking. Do you guys think that welder would hold it. The only reason why I was looking at that one was because I dont have a 220 in my storage building or gas. The frame is going to mount in the factory location of the rear end. I am going to use a pan hard. Still not to clear about the four link, or gearing. Please input. Not stupid sh*t please /ubbthreads/images/graemlins/cool.gif

mitsuturbo

Well-known member

If you're thinking you're going to be putting down enough horsepower to require a (bleep-ing) ford 8.8" rear end, then you sure as HELL should not even be CONSIDERING some (bleep-y) shipwreck freight welder to do the job! You can think this is "stupid (bleep)" if you want, but the fact that you are even asking this question has me wondering if this isn't some kind of ludicrous, over-the-top JOKE.

If you're going to do it. Do it right, and get the whole damn thing TIG WELDED, with a 220v setup, by a PROFESSIONAL.

EDIT: cleared some language to conform with Tech forum rules

If you're going to do it. Do it right, and get the whole damn thing TIG WELDED, with a 220v setup, by a PROFESSIONAL.

EDIT: cleared some language to conform with Tech forum rules

Last edited:

Terrance362

Well-known member

(bleep)(bleep)(bleep) thanks anyway. That is what questions are for and no this is not a (bleepin) joke thanks again.

Barnes

Well-known member

I was kinda thinking along the lines of what MT is. If you need to do some welding, tack it up at most, and get a pro with a TIG welder or a good MIG welder to finish this off. The last thing you need is your rear end falling out at 150mph as you pass through through the quarter mile.

toybreaker

iconoclast

- Joined

- Apr 30, 2006

- Messages

- 3,581

If you're really serious about this, don;t use a panhard bar with a four link.

You'll end up having problems with the thing hooking one way or another depending on the traction.

A panhard bar requires the rear end to shift sideways as it swings thru it's arc.

The amount of side steer will depend on the amount of squat, which will will totally depend on track prep.

A trully fast car on a fully prepped track will really show the limitations of ths system.

They can be dialed in, but there is steep learning curve, and if you;re making the power that requires stepping away from the stock set-up, you;re better off doing it once, and doing it right.

Instead, use a correctly engineered watts linkage.

A watts set-up is capable of handling anything you throw at without causing drama sixty foot out.

If you;re not familiar with what a watts linkage set-up looks like, one place to see what the layout looks like is under a first gen mazda rx-7.

You'll end up having problems with the thing hooking one way or another depending on the traction.

A panhard bar requires the rear end to shift sideways as it swings thru it's arc.

The amount of side steer will depend on the amount of squat, which will will totally depend on track prep.

A trully fast car on a fully prepped track will really show the limitations of ths system.

They can be dialed in, but there is steep learning curve, and if you;re making the power that requires stepping away from the stock set-up, you;re better off doing it once, and doing it right.

Instead, use a correctly engineered watts linkage.

A watts set-up is capable of handling anything you throw at without causing drama sixty foot out.

If you;re not familiar with what a watts linkage set-up looks like, one place to see what the layout looks like is under a first gen mazda rx-7.

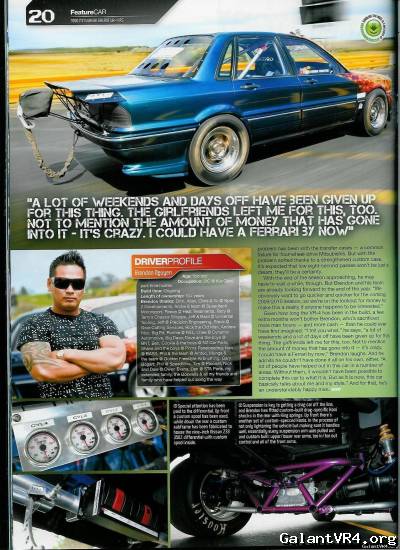

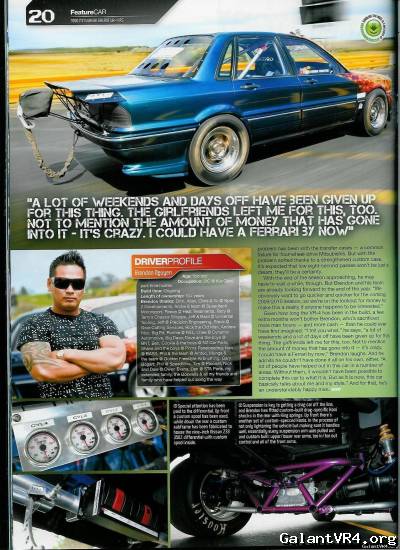

here you go buddy from the worlds fastest evo he uses toyota rear end but you can read the rest this may be a bit overkill but if its what you want go for it my friend

click

and here is a picture of it on the car and yes its still awd

and this is what it can do

click

click

click

and here is a picture of it on the car and yes its still awd

and this is what it can do

click

click

Last edited by a moderator:

A welded assembly is only as good as the weld quality and penetration. Doubtful you get that and especially a consistent bead with even a good MIG, let alone the chinese junk special, lol...There's only two things separating you from the road: tires and suspension; I'd rather have a tire blowout than something going wrong with the suspension like that (breaking off)...bad news for you and worse an innoncent victim. I'd have to see what you're talking about though (didn't read the entire thread), but doesn't sound like a good idea to skimp here and there's a lot involved with a properly functioning suspension and its geometry and such. Of course it *can* be done and sure it would be neat, but gotta really think about this and scratch that chinese sh*t (harbor freight) outta yo head, lol. /ubbthreads/images/graemlins/grin.gif

Hey look ma no mirrors or dog legs needed lol

Quoting RedTwo:

Someone mentioned this before, I'm sure of it...

Anywho, in that discussion Brendon Nguyen's VR4 RS with a Nissan Z33 350Z 9" rear diff came up. Looks like it just bolts right up.... to his custom body shell space frame! /ubbthreads/images/graemlins/uhh.gif :rolf:

Quoting RedTwo:

Someone mentioned this before, I'm sure of it...

Anywho, in that discussion Brendon Nguyen's VR4 RS with a Nissan Z33 350Z 9" rear diff came up. Looks like it just bolts right up.... to his custom body shell space frame! /ubbthreads/images/graemlins/uhh.gif :rolf:

Quoting Boostin21:

yea the APC EVO II is the way to go. the yellow car from Rob Barac.

utilizes a supra MA70 rear diff with a different ratio and custom axles.

thats what i am going to be using for my current project.

thought it was from a toyota hilux truck read the article again

yea the APC EVO II is the way to go. the yellow car from Rob Barac.

utilizes a supra MA70 rear diff with a different ratio and custom axles.

thats what i am going to be using for my current project.

thought it was from a toyota hilux truck read the article again

Quoting RedTwo:

Someone mentioned this before, I'm sure of it...

Anywho, in that discussion Brendon Nguyen's VR4 RS with a Nissan Z33 350Z 9" rear diff came up. Looks like it just bolts right up.... to his custom body shell space frame! /ubbthreads/images/graemlins/uhh.gif :rolf:

full article here

click

Someone mentioned this before, I'm sure of it...

Anywho, in that discussion Brendon Nguyen's VR4 RS with a Nissan Z33 350Z 9" rear diff came up. Looks like it just bolts right up.... to his custom body shell space frame! /ubbthreads/images/graemlins/uhh.gif :rolf:

full article here

click

boostedinaz

Well-known member

Quoting JNR:

A welded assembly is only as good as the weld quality and penetration. Doubtful you get that and especially a consistent bead with even a good MIG, let alone the chinese junk special, lol...There's only two things separating you from the road: tires and suspension; I'd rather have a tire blowout than something going wrong with the suspension like that (breaking off)...bad news for you and worse an innoncent victim. I'd have to see what you're talking about though (didn't read the entire thread), but doesn't sound like a good idea to skimp here and there's a lot involved with a properly functioning suspension and its geometry and such. Of course it *can* be done and sure it would be neat, but gotta really think about this and scratch that chinese sh*t (harbor freight) outta yo head, lol. /ubbthreads/images/graemlins/grin.gif

Agree 1000%.

i am all for learning how to do something and building as much of your project as possible, but sometimes the best bet is to know your limitations and farm certain work out. Suspension and frame are the last part of the car you want to fail because you used a cheap 110V welder that you got at Harbor Frieght.

I helped out at a fab shop for almost a year and there is a lot more involved than just plugging in the welder putting to pieces of metal close to each other and then welding. My suggestion is to find a good chassis chop and drop the car off to get this done.

A welded assembly is only as good as the weld quality and penetration. Doubtful you get that and especially a consistent bead with even a good MIG, let alone the chinese junk special, lol...There's only two things separating you from the road: tires and suspension; I'd rather have a tire blowout than something going wrong with the suspension like that (breaking off)...bad news for you and worse an innoncent victim. I'd have to see what you're talking about though (didn't read the entire thread), but doesn't sound like a good idea to skimp here and there's a lot involved with a properly functioning suspension and its geometry and such. Of course it *can* be done and sure it would be neat, but gotta really think about this and scratch that chinese sh*t (harbor freight) outta yo head, lol. /ubbthreads/images/graemlins/grin.gif

Agree 1000%.

i am all for learning how to do something and building as much of your project as possible, but sometimes the best bet is to know your limitations and farm certain work out. Suspension and frame are the last part of the car you want to fail because you used a cheap 110V welder that you got at Harbor Frieght.

I helped out at a fab shop for almost a year and there is a lot more involved than just plugging in the welder putting to pieces of metal close to each other and then welding. My suggestion is to find a good chassis chop and drop the car off to get this done.

Terrance362

Well-known member

Well thank you all. I am not going to buy a cheap welder. I am just going to mock it and get it welded by a local guy. I really understand that everyone has there own point of veiw and I respect that. /ubbthreads/images/graemlins/smile.gif I set out a goal and I am going to go through with my plans. I dont plan to disrespect the GVR4. If things just dont look right or feel right it will not hit the streets. Once I start to mock this up I will have pictures. But thank everyone again /ubbthreads/images/graemlins/applause.gif

Similar threads

- Replies

- 1

- Views

- 2K